How to choose a reliable DDP diamond dotted paper supplier?

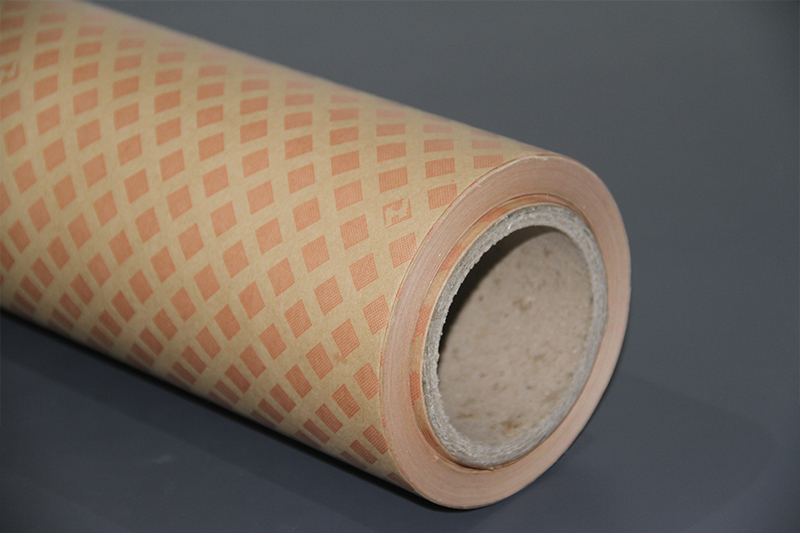

DDP diamond dotted paper is a key insulating material for electrical equipment such as oil-immersed power transformers. It uses high-performance insulating paper as the base material and is coated with a diamond-shaped special modified epoxy resin on the surface. The base material can be low-dissipation insulating paper or high-density insulating paper composite EM film. Transformer manufacturers choose reliable DDP suppliers to keep electrical equipment in good performance and extend their service life. So, how should companies choose?

Supplier qualifications and industry experience

When companies choose suppliers, qualifications and industry experience are important considerations.

Professional background: Priority is given to manufacturers or authorized agents who have long focused on insulation materials, especially those with experience in producing DDP paper. Such suppliers have a deeper understanding of the production process, material properties, etc. of DDP diamond dotted paper, and can better meet the needs of enterprises.

Production strength: Investigate whether the factory has precision coating and testing capabilities, which is the key to ensuring product consistency. Only with advanced equipment and professional technology can the quality of each batch of products be stable.

Industry reputation: Refer to peer recommendations or customer reviews to avoid suppliers with many market complaints. Good reputation is the embodiment of the supplier's long-term high-quality service. Choosing such a supplier can reduce the risk of cooperation.

Product quality verification

Product quality is directly related to the performance of electrical equipment, and enterprises must strictly verify it.

Sample testing: Ask the supplier for samples, and carefully check the uniformity of dispensing, viscosity stability, and whether there is residual glue after tearing. These details can intuitively reflect the quality of the product. If there is a problem with the sample, the batch product is likely to be substandard.

Batch sampling: Strict sampling at the beginning of cooperation to confirm whether the product meets the agreed standards. Various problems may arise in batch production, and sampling can promptly detect and prevent unqualified products from entering the production process.

Actual application test: Simulate real scenes such as die cutting and lamination to see if the product meets the needs. The actual application environment is complex, and only products that perform well in simulated scenes can adapt to actual production.

Supply stability

Stable supply is the guarantee for the normal production of enterprises, and enterprises need to focus on evaluation.

Inventory situation: Confirm that the supplier has stable inventory to avoid production affected by out-of-stock. Adequate inventory can cope with the sudden production needs of the enterprise and ensure the smooth progress of the production plan.

Delivery capacity: See whether the production cycle matches the demand and whether emergency orders can be responded to quickly. The production plan of the enterprise has a certain timeliness, and the supplier's delivery capacity must match it to avoid delays in production.

After-sales service: When quality problems occur, whether the supplier can handle them in time and provide solutions. Timely after-sales service can reduce the losses caused by quality problems and protect the rights and interests of the enterprise.

Cost-effectiveness and long-term cooperation

It is important to pursue cost-effectiveness and establish long-term cooperative relationships under the premise of ensuring quality.

Reasonable quotation: Compare the prices of multiple companies and avoid options that are too high or significantly lower than the market price. Too high prices will increase costs, and too low prices may have quality risks. Reasonable prices are the best choice.

Long-term agreement: After stable cooperation, negotiate more favorable prices and service terms. Long-term cooperation can make suppliers pay more attention to the needs of enterprises, and enterprises can also obtain more favorable cooperation conditions.

Value-added services: High-quality suppliers may provide technical support (such as glue point optimization suggestions) or customized services. These services can help companies improve production efficiency, solve practical problems, and enhance the value of cooperation.

Field visits and case references

Field visits and case references can allow companies to have a more comprehensive understanding of the strength of suppliers.

Visit the factory, observe the production environment, equipment and management level, and judge whether it is standardized. A neat production environment, advanced equipment and scientific management are the embodiment of the supplier's strength.

Understand whether the supplier has served customers with similar needs and verify its actual capabilities. Suppliers who have served similar customers are more familiar with relevant needs and standards and can better meet the requirements of enterprises.

DDP purchase suggestions

1. According to the above standards, list 3-5 candidate suppliers to prepare for subsequent inspections.

2. Focus on visiting the supplier's production workshop and quality inspection laboratory to verify its technical capabilities and quality control, and intuitively understand the supplier's strength.

3. Test the supplier's delivery speed, product quality and after-sales service response through actual orders to further test the supplier's comprehensive capabilities.

4. Sign an annual framework agreement with suppliers who have passed the assessment, lock in prices and service terms, establish a stable cooperative relationship, and guarantee the company's long-term production needs.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele