Factory Insulation Paper Selection: A Guide for Procurement Teams to Quickly Evaluate Performance and Suitability

As a critical insulation material in electrical equipment, insulation paper plays an essential role in ensuring the safe and stable operation of motors, transformers, capacitors, and other devices. To ensure that the selected product delivers high performance and aligns with actual factory requirements, procurement personnel must consider multiple factors when choosing insulation paper.

Understanding Types of Insulation Paper

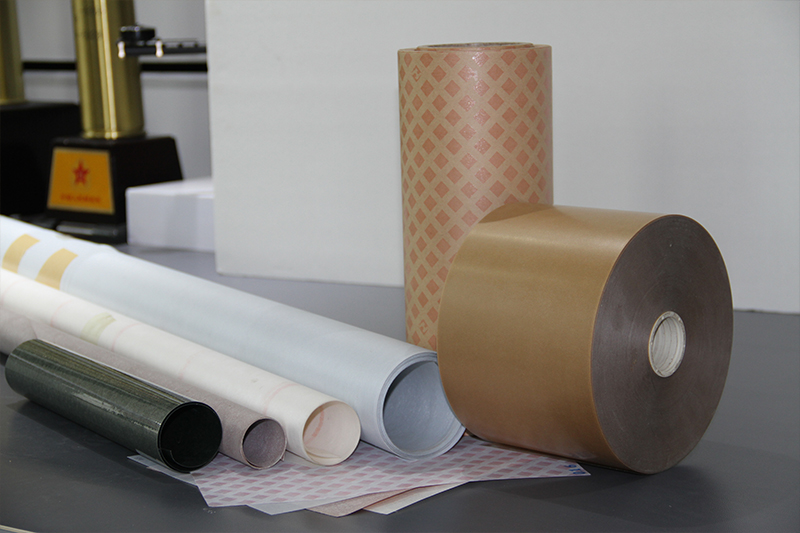

Insulation paper comes in various types, with common examples including kraft paper, crepe paper, and polyester film composite paper. Each type differs significantly in performance and application scenarios. Kraft paper, with its high mechanical and dielectric strength, is an ideal choice for general electrical insulation. In contrast, polyester film composite paper stands out for its excellent heat resistance and corrosion resistance, making it suitable for harsh environments with high temperatures and humidity.

Before selecting insulation paper, it's important to clarify the following three key questions:

· What is the application scenario? For instance, is it for high-voltage motor insulation, interlayer insulation in transformers, or cable wrapping? Different scenarios require different levels of dielectric strength, flexibility, and other performance characteristics.

· Will the operating environment be harsh? High temperatures inside motors, humid outdoor conditions, or oily surroundings near gearboxes can all impact the performance of insulation paper. Such conditions help eliminate incompatible materials early in the selection process.

· What is the procurement budget? For standard applications, cost-effective materials like PET film may suffice. For special requirements, consider premium options such as Nomex® or other high-performance insulation papers.

Key Performance Criteria of Insulation Paper

1.Basic Physical Inspection

Visual Check: Assess the surface smoothness of the insulation paper by visual inspection. High-quality insulation paper should be free from bubbles, cracks, impurities, or delamination.

Flexibility Test: Manually bend the material. A good-quality insulation paper should withstand repeated folding without breaking or flaking.

Thickness Uniformity Check: Use a caliper or thickness gauge to measure multiple points. Excessive variation in thickness increases the risk of partial discharge, potentially compromising equipment safety.

2.Electrical Performance Testing

Breakdown Voltage Estimation: Request a third-party test report from the supplier to ensure the material can withstand at least twice the rated voltage of the equipment. For on-site testing, use a high-voltage generator to gradually increase voltage until breakdown occurs, observing for signs of arcing or burning.

Insulation Resistance Test: Use a megohmmeter to measure resistance between the material and a metal conductor. High-quality materials should exhibit near-infinite resistance (practically ≥100 MΩ). Compare values in dry and humid conditions—if resistance drops significantly in high humidity, the material is unsuitable for such environments.

3.Mechanical Performance Simulation Tests

Tensile Strength Test: Manually stretch the material until it breaks. High-grade insulation paper should resist tearing under tension. For example, motor insulation paper must withstand mechanical stress during installation.

Abrasion Resistance Test: Gently rub the surface with sandpaper or a metal brush to check for fraying or damage. This test is especially important for applications involving frequent friction within the equipment.

Key Points for Supplier Evaluation

Certifications: Prioritize suppliers with recognized certifications such as UL and ISO 9001. Also consider their sample delivery efficiency—suppliers who can provide samples within 3 days are generally more reliable.

Industry Experience: Check whether the supplier has application cases in your industry. For example, if a transformer manufacturer has been sourcing insulation paper from the same supplier for over three years, it’s a strong indicator of consistent product quality.

Cost Consideration: Don’t focus solely on unit price. Compare long-term usage costs. For instance, Nomex® lasts three times longer than PET, which may make it a more cost-effective option over time.

Supplier Communication Tips

Ask for Use Cases, Not Just Specs: Instead of asking about technical parameters, inquire whether the insulation paper has been used in similar electrical equipment and what feedback was received. Real-world applications help assess product suitability.

Request Samples for Field Testing: Ask for A4-sized samples and test them in actual equipment for 1–2 days. Evaluate performance based on real-world operation to determine if the product meets your requirements.

Compare Service, Not Just Price: When selecting a supplier, give preference to those who offer technical support—such as recommending compatible adhesives. High-quality service ensures better long-term reliability and ease of use.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele