How to Identify a Dry-Type Transformer: Key Features and Applications?

In modern power systems, dry-type transformers are widely used in commercial buildings, industrial facilities, and infrastructure projects thanks to their oil-free operation, high safety, and environmental adaptability. Understanding dry-type transformer features is essential for correct selection, installation, maintenance, and ensuring reliable power system performance. Below is a detailed guide on identification methods based on appearance, nameplate markings, insulation materials, and application scenarios.

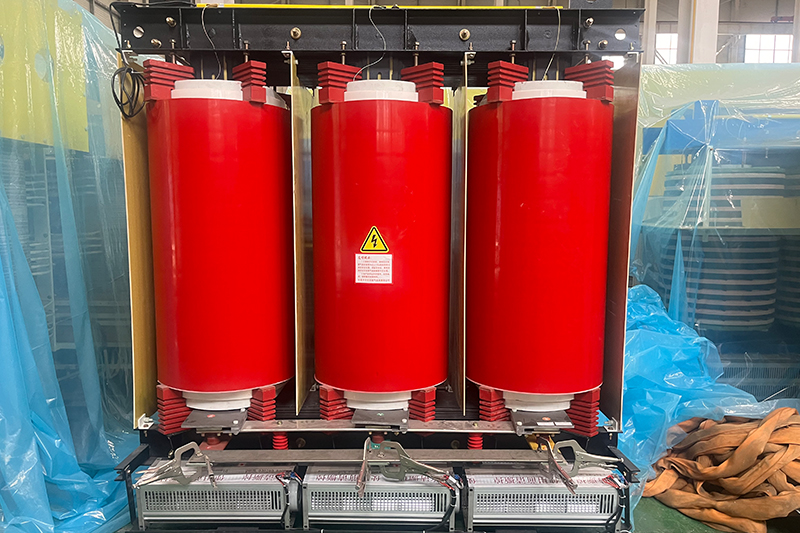

1. Appearance

The most distinct dry-type transformer features are visible in its structure and design, which differ greatly from oil-immersed transformers:

No Oil Tank or Conservator: Dry-type transformers have no metal oil tank, oil conservator, oil level gauge, or cooling pipes, resulting in a more compact and lighter structure.

Winding Configuration: Open (non-encapsulated) designs feature exposed windings coated with insulating varnish or wrapped in Nomex paper, while epoxy-encapsulated designs completely seal windings in epoxy resin for improved dust and moisture resistance.

Heat Dissipation: Cooling relies on natural air (AN) or forced air (AF) with ventilation holes, heat sinks, or fins—unlike the tubular heat sinks in oil-immersed units.

2. Insulation Material

Dry-type transformers use air as the cooling medium. Windings and cores are exposed to air, with external insulation made from flame-retardant glass fiber-reinforced epoxy resin, offering high heat resistance and mechanical strength. This is in stark contrast to oil-immersed transformers, which immerse windings in transformer oil inside a large metal tank.

3. Nameplate and Labeling

The transformer nameplate provides critical identification details:

Model Codes: Domestic models often start with "SC" (e.g., SCB10, SCB13). "S" denotes three-phase, "C" indicates solid insulation (epoxy resin casting), "B" means foil winding, and "R" refers to copper wire winding. Imported models may include terms like “Dry-type” or “VPI” (Vacuum Pressure Impregnation).

Technical Data: Parameters such as rated capacity, voltage, current, insulation class (commonly F or H), and cooling method (AN or AF) confirm its type. A lack of oil immersion indicators further validates it as a dry-type transformer.

4. Typical Application Scenarios

Thanks to their oil-free, fireproof, and environmentally friendly nature, dry-type transformers are used in:

• Indoor power distribution for malls, hospitals, schools, and high-rise buildings.

• Enclosed or hazardous locations such as subways, tunnels, and mines.

• High-cleanliness environments like data centers, laboratories, and precision manufacturing facilities.

5. Common Dry-Type Transformer Types

Epoxy-Cast (SCB Series): Fully encapsulated in epoxy resin for superior dust and moisture resistance, suitable for humid or dusty sites.

Open Type (SG Series): Varnish-coated windings without full sealing, ideal for clean, dry indoor power rooms.

Amorphous Alloy (SCBH Series): Extremely low no-load losses for energy efficiency, perfect for green buildings and data centers.

By examining structural design, insulation materials, nameplate parameters, and installation environment, you can accurately identify a dry-type transformer and understand its unique operational advantages. Recognizing these dry-type transformer features ensures optimal selection, safe operation, and reliable maintenance in diverse power system applications.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele