Bakelite vs. Other Insulation Materials: Property Comparison and Application Scenarios

In the field of electrical insulation, material selection directly impacts equipment performance, safety, and cost. This article will compare the core properties of bakelite with epoxy board and plastic insulation materials (PVC, PE, PP, etc.), analyze their application scenarios, and help readers select the optimal material for their needs.

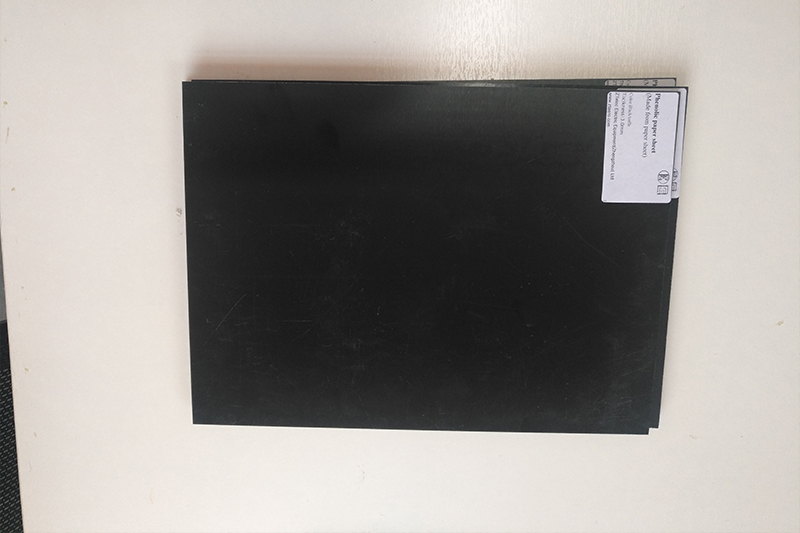

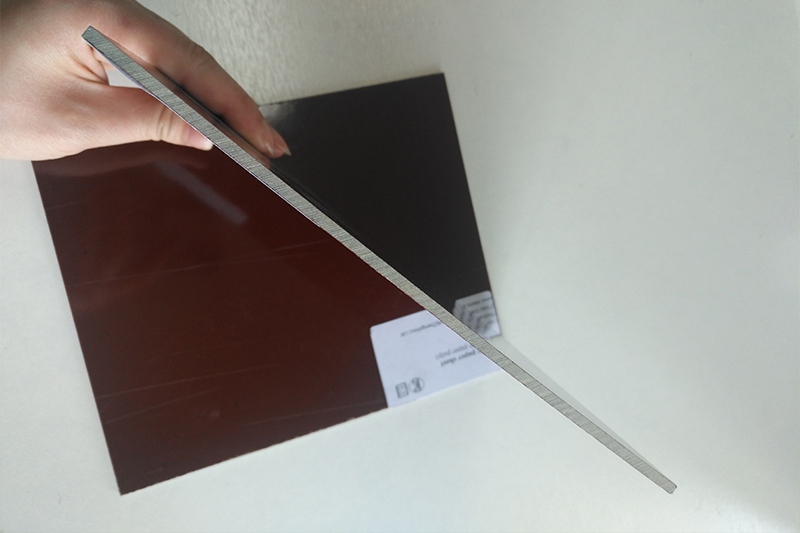

Bakelite (Phenolic Laminated Paperboard)

Bakelite is a traditional insulation material made by impregnating kraft paper with phenolic resin and laminating it under high temperature and high pressure. Its balanced performance and low cost make it widely used in medium and low voltage applications.

►Core Characteristics

High Mechanical Strength: Bakelite has excellent bending and compressive resistance. It is suitable for use as structural support, meeting the mechanical requirements of most equipment.

Moderate Heat Resistance: It is able to withstand the temperature requirements of conventional electrical environments and operate stably at normal operating temperatures.

Stable Insulation: It has strong arc resistance, stable insulation withstanding medium and low voltage fields, and reliable insulation.

Significant Cost Advantage: Raw materials are readily available, processing is simple, and the price is lower than high-performance materials such as epoxy board and fiberglass board.

►Limitations:

Highly hygroscopic, long-term exposure to humidity can lead to moisture absorption, potentially degrading insulation performance. Varnish coating or sealing are required to protect against moisture.

Bakelite has poor impact resistance and high brittleness. It requires avoiding severe mechanical shock to prevent cracking.

►Typical Applications

Electrical Insulating Structural Parts:

Motor end caps, transformer frames, switchgear partitions, and other components that require both mechanical support and insulation. Advantages include low cost and high strength, making them suitable for high-volume production.

Mechanical Protective Parts:

Tool handles, equipment gaskets, and other applications requiring wear and oil resistance.

Note: Avoid humid environments; moisture absorption may degrade insulation performance.

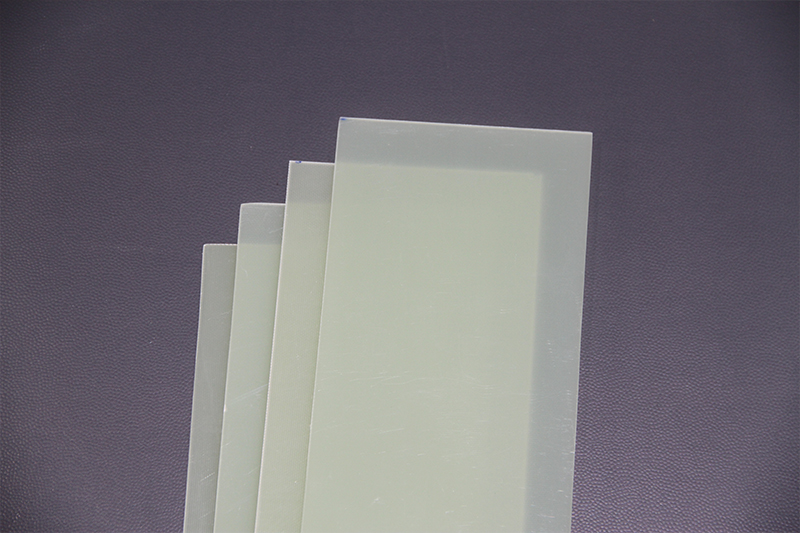

Epoxy Sheet (Epoxy Glass Fiber Cloth Laminate)

Epoxy sheet is made of epoxy resin-impregnated glass fiber cloth laminated together. It is the preferred insulation material for high-voltage and high-temperature environments, offering superior performance compared to bakelite, but at a higher cost.

►Core Features

Excellent Heat Resistance: Epoxy sheet is suitable for equipment operating at high temperatures for extended periods, maintaining stable performance even in high-temperature environments.

Excellent Mechanical Properties: Highly resistant to bending and impact, with high dimensional stability, and resistant to deformation or damage from vibration and shock.

Top-Notch Insulation: Excellent corona and tracking resistance, capable of withstanding high voltage and high-frequency electric fields, providing outstanding insulation.

Chemical Resistance: Excellent resistance to acids, alkalis, and organic solvents, making it suitable for harsh industrial environments.

Higher Cost: Pricier than bakelite, making it more suitable for applications requiring stringent performance requirements.

►Applications

High-voltage and high-frequency electrical insulation:

Insulation components for power transformers, contact brackets for high-voltage switches, and substrates for high-frequency capacitors. Advantages include heat resistance, arc resistance, and chemical resistance, along with a long service life and reduced equipment maintenance.

New Energy Field:

Insulating components in photovoltaic inverters and wind turbine converters must withstand long-term high temperatures and high voltage fluctuations. The stability of epoxy boards ensures reliable operation of these devices.

Plastic Insulation Materials (PVC, PE, PP)

Plastic insulation materials, represented by polyvinyl chloride (PVC), polyethylene (PE), and polypropylene (PP), dominate the low-voltage, ambient temperature market thanks to their extremely low cost and flexibility.

►Core Features

Extremely Low Cost: Prices are significantly lower than bakelite, making them suitable for low-cost mass production.

Good Flexibility: Bendable and foldable, with minimal processing effort, they are suitable for insulation applications requiring deformation (such as cable sheathing and flexible connectors).

Poor Heat Resistance: Unable to withstand high temperatures, they can only be used at relatively low temperatures.

Fair insulation performance: Plastic insulation material is prone to aging after long-term use, and the insulation performance declines significantly over time, only meeting the basic insulation requirements.

►Applicable Applications

Low-Voltage Electrical Sheathing:

Cable outer sheaths and wire insulation layers (such as PVC-jacketed wire) utilize their low cost and flexibility to meet basic insulation requirements at low voltages and ambient temperatures.

Temporary Insulation:

Temporary insulation tapes used in electrical repairs are easy to apply and tear, and their insulation performance generally meets the requirements for temporary low-voltage protection.

Selection Recommendations

Different insulation materials have their own advantages and disadvantages, and their applicable scenarios also vary significantly. Bakelite offers a balanced combination of cost, strength, and insulation stability, but requires attention to moisture and impact protection. Epoxy insulation offers high-temperature, high-voltage, and corrosion resistance, offering top-tier performance but at a higher cost. Plastic insulation materials are extremely low-cost and flexible, but suffer from poor heat resistance and aging.

Selection Recommendations:

If you're looking for cost-effectiveness and the environment is dry and moderate, bakelite is the preferred choice.

If the insulation needs to withstand high voltage, high temperature, or harsh environments, epoxy insulation is a more reliable option.

For low-voltage, temporary, or low-cost applications, plastic insulation can meet basic needs.

The optimal application of insulation materials requires a comprehensive assessment of the actual operating conditions, including temperature, voltage, humidity, and cost budget.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele