Electrical Laminated Wood in China: Prices and Tips

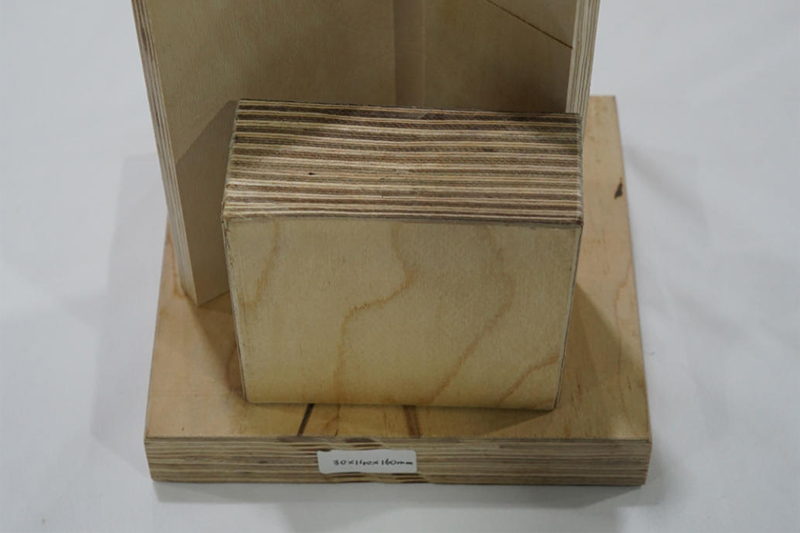

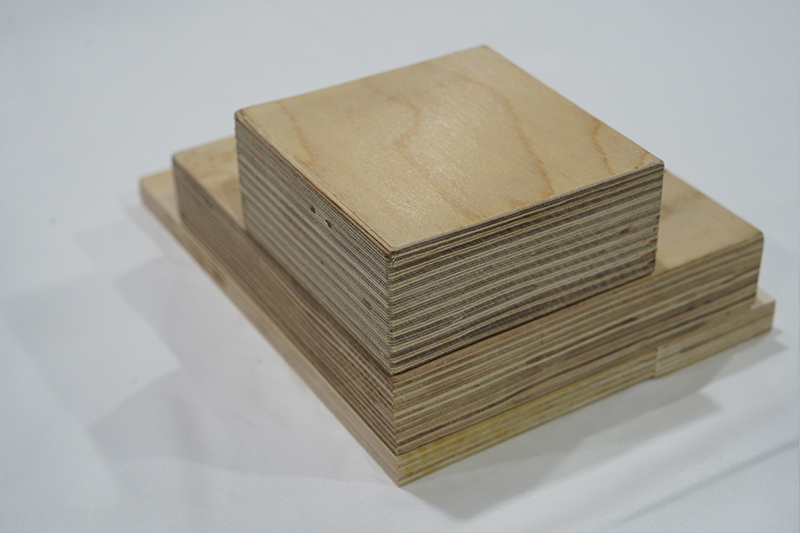

Electrical laminated wood is a key insulating structural material in high-voltage electrical equipment, widely used in power transformers, reactors, and other equipment. It is often processed into components such as core clamps, spacers, and support bars. Its production process uses high-quality wood (such as birch and basswood) as the base material. The veneer is impregnated with phenolic resin and then hot-pressed and cured under high temperature and high pressure. The final product possesses extremely high mechanical strength, excellent insulation properties, and stable dimensional characteristics.

Electrical Laminated Wood Price Analysis

The price of electrical laminated wood is not a fixed value. It is influenced by multiple factors, resulting in significant market fluctuations.

1. Factors Influencing Price

Raw Material Grade: As the primary influencing factor, the wood type and veneer quality directly determine the cost. Laminated wood made from imported birch from Northern Europe offers the best performance and the highest price. Domestic birch and basswood, however, are relatively cheaper due to cost differences.

Insulating Resin Content: Resin content is often indirectly reflected through specific gravity or density. Higher resin content indicates superior electrical insulation and mechanical properties, and consequently, higher prices. For example, high-density products with a density greater than 1.0 g/cm³ are priced higher than standard-density products.

Dimensions: This is the most direct factor affecting cost. The thicker the product and the larger its surface area, the higher the amount of raw materials and hot-pressing costs required, leading to exponential price increases. This is especially true for oversized, monolithic laminated wood panels, which often command significantly higher prices.

Process Requirements: Additional processing, such as pre-drilling, planing, sanding, and special chamfering, increases labor and processing costs, leading to higher final prices.

Purchase Quantity: Purchase size significantly impacts unit price. Annual large-volume orders from transformer manufacturers often command significantly lower unit prices than small-volume sample orders.

Manufacturer Brand: Domestic top-tier brands, with their more consistent quality, command higher prices than products from smaller and medium-sized manufacturers.

2. Approximate Price Range (For reference only: actual pricing is subject to manufacturer's quotation)

Because size is the largest variable in price fluctuations, the following is a rough estimate:

Low-price range: Approximately 12.35 to 15 RMB, primarily for small-volume custom orders or special specifications.

Mainstream price range: Approximately 28 to 40.85 RMB, covering standard products with common specifications and standard materials.

High-price examples: Some products using special materials or imported raw materials are priced around 35 RMB.

Important note: The above prices only reflect approximate market levels. The best way to obtain accurate pricing is to contact the manufacturer or supplier directly and provide detailed technical drawings (including material requirements, dimensions, tolerances, performance specifications, etc.) for a formal quotation.

Tips for Purchasing and Using Electrical Laminated Wood

1. Select Reliable Suppliers

Verify Certifications: Prioritize manufacturers certified to the ISO9001 quality management system. Products must include third-party testing reports to ensure performance complies with national standards (such as GB/T 13041) or international standards (such as IEC).

Evaluate Technical Capabilities: Focus on verifying the manufacturer's ability to produce products with the desired dimensions and performance. This is especially true for products with extra-large or extra-thick specifications or special processing requirements. Verify the manufacturer's process compatibility.

Reference Industry Reputation: Understand the manufacturer's cooperation cases and market reputation in the transformer industry. Usually, suppliers that have cooperated with large transformer enterprises are more reliable.

2. Clarify Technical Requirements and Standards

During the inquiry and ordering stages, suppliers must be provided with clear technical specifications, including the following:

Material Requirements: Specify the wood species, such as Nordic birch or domestic birch.

Density or Specific Gravity: Specify the required value, for example, ≥1.0 g/cm³.

Dimensions and Tolerances: Provide detailed processing drawings, clearly specifying all dimensional parameters and the allowable tolerance range.

Performance Indicators: Where necessary, indicate key performance requirements, such as dielectric strength perpendicular to the plies, dielectric strength parallel to the plies, water absorption, and flexural strength.

Processing Requirements: Specify whether any final processing, such as drilling, milling, or polishing, is required.

3. Quality Control and Acceptance

Incoming Material Inspection: Upon receipt of goods, samples must be inspected to verify dimensional compliance and to identify any cosmetic defects (such as cracks, delamination, or scarring).

Performance Retesting: For critical projects, samples may be sent to a third-party testing agency for retesting of key insulation and mechanical properties to ensure consistency with the product specifications.

4. Standardized Storage and Processing

Storage Environment: Store the product in a dry, well-ventilated environment. Avoid moisture, as moisture absorption can directly affect the insulation properties of electrical laminated wood.

Processing Requirements: When performing machining operations such as turning, milling, and drilling, use sharp carbide tools to ensure a smooth surface and prevent burrs and carbonization that could affect insulation performance.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer