What is the best insulation paper for motor winding?

In the motor manufacturing industry, insulating paper is a critical material for ensuring safe winding operation. Its performance directly impacts the motor's efficiency, service life, and reliability. As motors continue to develop toward higher power density, higher thermal ratings, and smaller sizes, traditional insulation materials are increasingly unable to meet these demands. This article will detail several of the most ideal types of insulating paper for motor windings.

1. Nomex®

This type of insulating paper is often considered a benchmark product with excellent overall performance. Originally developed by DuPont, it is now also produced by other companies.

Advantages:

Outstanding high-temperature resistance: Insulation materials classified as H-class (180°C) or higher (up to 220°C) offer extremely long thermal life.

Excellent mechanical strength: Excellent tear, puncture, and abrasion resistance ensures resistance to damage during winding and inserting operations.

High dielectric strength: Excellent electrical insulation strength ensures reliable operation.

Good chemical stability: Resistant to most solvents, oils, and corrosive chemicals, making it suitable for use in harsh environments.

Excellent flame retardancy: It has self-extinguishing properties, will not melt, and meets strict flame retardant standards.

Disadvantages:

Highest cost among all types of insulation paper.

Applications:

Widely used in motors requiring high performance and reliability, such as:

Aerospace motors

Traction motors, such as those used in high-speed rail and subways

Variable frequency motors (VFDs), which must withstand high-frequency pulse voltages

Explosion-proof motors and mining motors

High-efficiency, energy-saving motors, and new energy vehicle drive motors

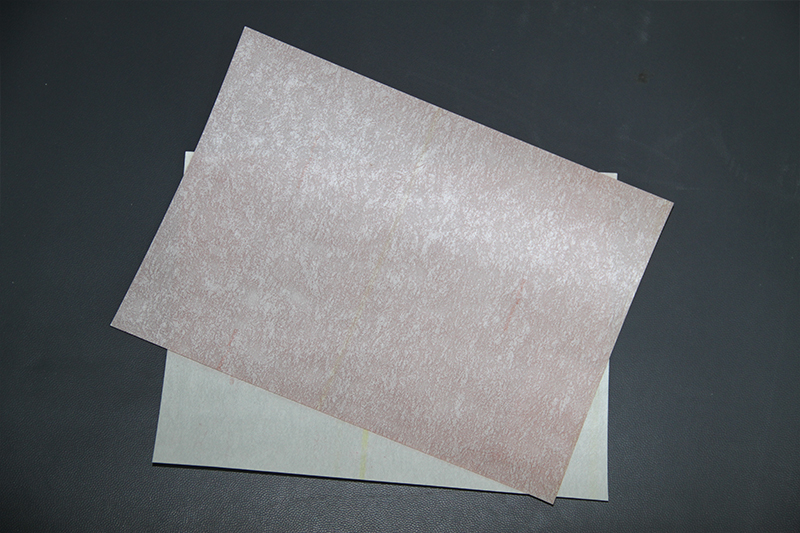

2. DMD Composite Material

This is a three-layer composite insulation material consisting of two layers of polyester nonwoven fabric (Dacron) sandwiched with a layer of polyester film (Mylar).

Advantages:

Excellent cost-effectiveness: Significantly lower cost than Nomex paper and NMN composite materials.

Good overall performance: It offers excellent electrical performance, mechanical strength, and heat resistance, and is classified as a Class B (130°C) or Class F (155°C) insulation material.

Disadvantages:

Its heat resistance and chemical stability are inferior to those of Nomex paper.

Applications:

As the most widely used general-purpose motor insulation material, it is suitable for:

Household appliance motors, such as air conditioners and washing machines

Small and medium-sized general-purpose motors used in the industrial sector

Applications where operating temperature and performance requirements are not extremely stringent

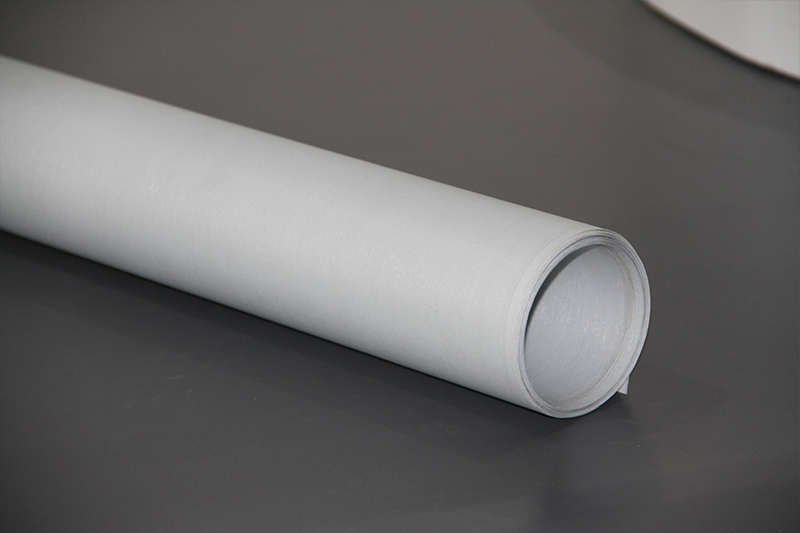

3. NMN Composite Material

This material is also a three-layer composite insulation material, consisting of two layers of Nomex paper sandwiched with a layer of polyester film (Mylar).

Advantages:

Extremely high dielectric strength: The polyester film provides excellent electrical insulation, making it particularly suitable for use in high-voltage motors.

Excellent mechanical properties: Combining the mechanical strength of Nomex paper with the toughness of polyester film.

Excellent corona resistance: Excellent resistance to the high-frequency pulse voltages generated by variable-frequency drives.

Disadvantages:

Higher price than pure Nomex paper and slightly less flexible.

Applications:

High-voltage motors with voltage ratings of 6kV, 10kV, and above

Phase-to-phase and slot insulation in variable-frequency motors

Insulation of generator windings

How to choose insulation paper for motor windings?

Determine the temperature rating: First, determine whether the motor's designed temperature rise corresponds to Class B, Class F, or Class H. This is the primary basis for selecting insulation material.

Consider the voltage rating: For high-voltage motors (e.g., voltages exceeding 1000V), materials with extremely high dielectric strength, such as NMN composite materials, must be selected. Low-voltage motors, on the other hand, offer more flexibility in material selection.

Determine whether the motor will be used for variable-frequency drives: The windings of variable-frequency motors are subject to high-frequency pulse voltages, which are prone to partial discharge (corona). Therefore, corona-resistant insulation materials, such as Nomex paper or specially treated NMN composite materials, are required.

Analyze environmental factors: Will the motor be exposed to oils, solvents, chemicals, or high humidity? If so, the chemical stability advantages of Nomex paper will be significant.

Consider budget constraints: While meeting motor performance requirements, balance cost and performance. DMD composite materials offer the best value for money, while Nomex paper and NMN composite materials are suitable for applications where cost is not a concern but ultimate reliability is desired.

If cost is not a factor, and the sole consideration is the pursuit of ultimate overall performance, reliability, and durability, Nomex® is undoubtedly the industry's recognized best choice. However, for the vast majority of industrial applications, DMD composites or even higher-grade F-grade DMD composites fully meet the requirements and offer the best cost-effectiveness.

When selecting specific insulation paper, it is recommended to consult with insulation material suppliers (such as DuPont and XUJUE ELECTRICAL) or motor manufacturer engineers. They can provide the most suitable option based on your motor's specific design parameters.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer