Application of SMC Insulation Boards in Switchgear: Enhancing Safety and Durability

In the power transmission, distribution, and industrial sectors, switchgear is a core device ensuring the safe and reliable distribution of electricity. The performance and reliability of its internal components directly determine the stability of the entire power system. Among the many materials used, SMC insulation boards (Sheet Molding Compound) are increasingly becoming the preferred choice in high-end switchgear design. How exactly do they improve equipment safety and durability? This article provides an in-depth analysis.

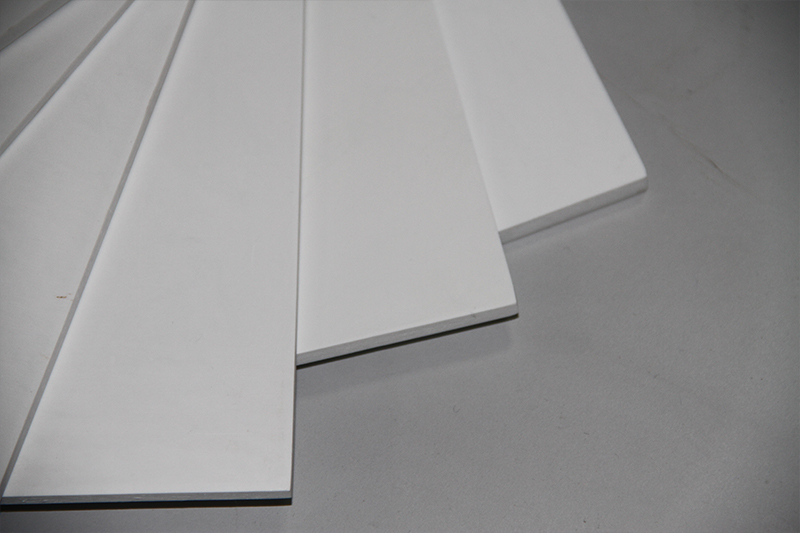

What Is an SMC Insulation Board?

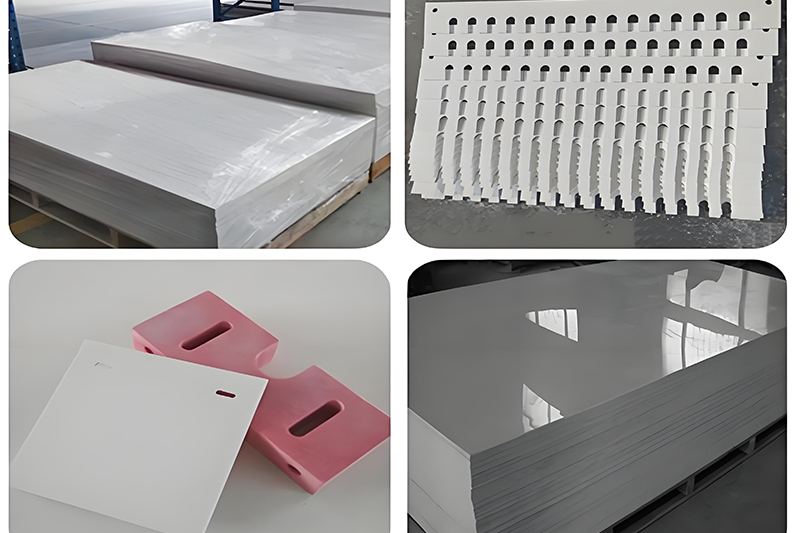

SMC is an advanced composite material made from unsaturated polyester resin, glass fiber, fillers, and additives, molded under high temperature and high pressure. It offers excellent electrical performance, mechanical strength, and environmental resistance. These properties make it highly suitable for switchgear structural and insulating parts such as partitions, supports, and arc shields.

How Do SMC Insulation Boards Enhance Switchgear Safety?

Ensuring operator safety and grid stability is the primary mission of switchgear, and SMC excels in this regard.

1.Outstanding Electrical Insulation

SMC materials possess extremely high insulation resistance and dielectric strength, effectively withstanding normal operating voltages as well as transient overvoltages (such as switching surges or lightning strikes). They act as reliable barriers, strictly separating high-voltage live parts (e.g., busbars, circuit breakers) from grounded or operator-accessible areas. This greatly reduces the risks of arc faults and electrical breakdown, providing protection for both equipment and personnel.

2.Excellent Flame Retardancy

Fire safety is critical. SMC insulation boards typically achieve UL94 V-0, the highest flame-retardant rating. They self-extinguish quickly when exposed to open flames and do not produce molten drips, effectively preventing flame spread. In the event of arc faults inside the switchgear, this property confines the incident locally and prevents catastrophic fires.

3.High Mechanical Strength

Switchgear must withstand the weight of internal components, electrodynamic forces, and mechanical stress during transport and installation. With its dense molded structure, SMC offers high strength and rigidity. Partitions and supports made from SMC resist deformation and fracture, maintaining precise component positioning and ensuring safe clearances (creepage and electrical distances) are always in compliance.

4.Strong Arc Resistance

In polluted or humid environments, insulating surfaces can develop conductive paths, leading to “tracking.” SMC materials have excellent arc resistance and tracking resistance, preventing carbonized paths from forming and avoiding short circuits caused by insulation degradation.

How Do SMC Insulation Boards Improve Switchgear Durability?

Beyond safety, long-term stability (durability) directly impacts operational costs and power supply reliability.

1.Exceptional Corrosion and Aging Resistance

Unlike metals (prone to rust) and some plastics (prone to aging and embrittlement), SMC insulation boards have excellent resistance to acids, alkalis, and salts, and are immune to moisture and mold. Whether in coastal, high-salt environments or heavily polluted industrial areas, SMC maintains stable performance and significantly outlasts metal components, reducing maintenance and replacement needs.

2.Excellent Thermal Stability

Switchgear generates heat during operation due to current losses. With low thermal conductivity and high heat resistance (continuous operating temperature above 155 °C), SMC materials serve as effective thermal barriers while maintaining structural stability under high temperatures without deformation or degradation.

3.Lightweight and Design Flexibility

SMC is much lighter than metals, reducing overall switchgear weight and simplifying transport and installation. It can also be molded into complex shapes in a single process, enabling functional integration and reducing the number of parts and joints. Simpler structures mean fewer potential failure points, improving overall equipment reliability.

4.Low Maintenance Costs

SMC insulation boards are essentially maintenance-free—they do not rust, corrode, or age, and require no protective coating. Switchgear made with SMC demands minimal upkeep throughout its service life, significantly lowering lifecycle operating and maintenance costs.

In switchgear design, material selection sets the upper limit of equipment performance. With its combination of high insulation, flame retardancy, mechanical strength, corrosion resistance, and long service life, SMC insulation boards have become the ideal solution for enhancing both safety and durability.

For switchgear manufacturers and end users alike, choosing switchgear built with SMC insulation boards means higher safety, longer service life, and lower total cost of ownership.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele