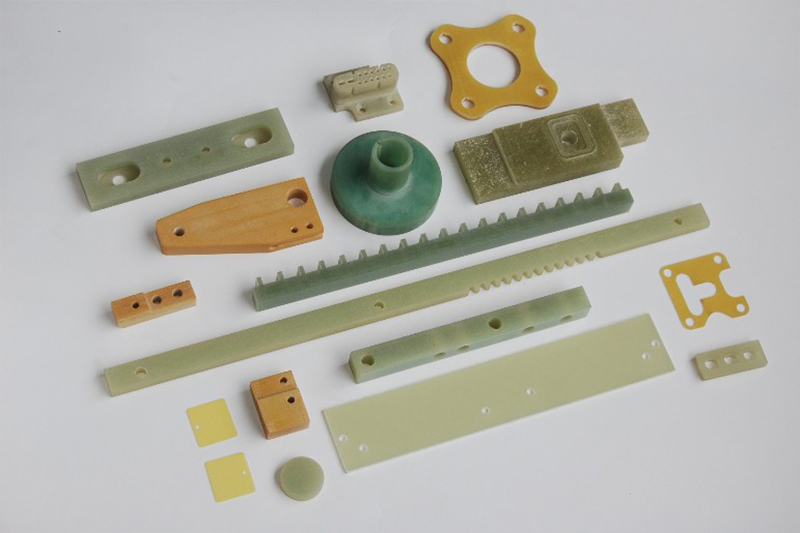

FR4 Epoxy Board: The First Choice for Insulating Gaskets?

FR4, short for Flame Retardant 4, is a composite material made by impregnating electronic-grade fiberglass cloth with epoxy resin and then curing it under high temperature and pressure. FR4 mainly consists of two parts:

♦ Matrix: Epoxy resin. Its function is to provide FR4 with excellent electrical properties, chemical resistance, and adhesion.

♦ Reinforcing Material: Fiberglass cloth. Its function is to provide FR4 with reliable mechanical strength and dimensional stability.

Reasons Why FR4 is the First Choice for Insulating Gaskets

1. Excellent Electrical Insulation Performance

Electrical insulation performance is the core value of FR4 as an insulating gasket, specifically reflected in the following three points:

High Dielectric Strength. FR4 can withstand extremely high voltages without breakdown, effectively preventing short circuits and ensuring the safety of equipment operation and operators.

High Volume and Surface Resistivity. FR4 itself is non-conductive, effectively isolating current and avoiding faults caused by current leakage.

Stable Dielectric Constant. The electrical performance of FR4 remains stable over a wide temperature and frequency range, making it suitable for high-frequency circuit applications.

2. Reliable Mechanical Properties

Insulating gaskets typically require structural support and fixation. FR4 fully meets these needs, specifically:

High mechanical strength and rigidity. FR4 can withstand certain pressure and stress, and is not easily deformed or damaged during installation and fastening.

Excellent impact resistance and toughness. FR4 exhibits greater stability when facing impacts and vibrations, is less prone to breakage, and ensures effective support.

3. Excellent Heat Resistance

Electronic and electrical equipment generates heat during operation. FR4's heat resistance effectively addresses this issue, with the following advantages:

Standard FR4 material has a long-term operating temperature range of 130°C - 155°C, meeting the operating temperature requirements of most electronic devices.

In high-temperature environments, the shape and core properties of FR4 do not change significantly, ensuring stable equipment operation.

Main Applications of FR4 Insulating Gaskets

FR4 insulating gaskets, due to their comprehensive advantages, are widely used in various applications requiring electrical isolation, mechanical support, and physical separation. Specifically, they can be divided into the following three main areas:

1. Power Electronics and Electrical Equipment

- Transformers: FR4 gaskets are used between coils and between coils and the core, providing both insulation and fixed support.

- Motors and Generators: FR4 gaskets can be used as insulating gaskets between the stator and end covers, and also as internal winding supports, ensuring stable motor operation.

- High and Low Voltage Switchgear/Distribution Boxes: FR4 gaskets are used for insulation between busbars, circuit breakers, disconnect switches, and other components and the mounting plate to prevent leakage faults.

- Relays and Contactors: FR4 gaskets are used to isolate live parts from the casing and mounting brackets, improving equipment safety.

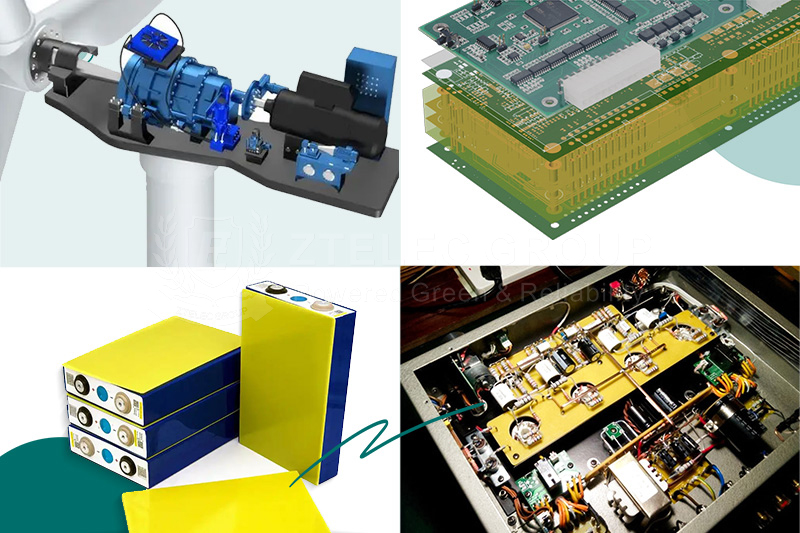

2. Industrial Control and Automation

- Frequency Converters and Servo Drives: FR4 gaskets are used for insulation between internal power modules (such as IGBTs) and heat sinks. In some applications, thermally conductive and insulating silicone pads are used. However, when extremely high insulation and mechanical strength requirements are needed, FR4 sheets or a combination of FR4 and other materials are required.

- Control Circuit Board (PCB): FR4 sheets can serve as support pillars or spacers for the PCB, isolating the motherboard from the metal chassis and preventing short circuits caused by contact issues.

3. New Energy Sector

- Photovoltaic Inverters: FR4 gaskets are used for insulation support of busbars on both the DC and AC sides, ensuring stable power transmission from photovoltaic systems.

- Wind Power Converters: FR4 gaskets are used for the installation and insulation of high-power modules, adapting to the high-intensity operating requirements of wind power equipment.

- Electric Vehicles: FR4 gaskets are used for internal insulation and isolation of high-voltage components such as Battery Management Systems (BMS), On-Board Chargers (OBC), and drive controllers, improving the safety of electric vehicle high-voltage systems.

In industrial and electronic applications with high reliability and safety requirements, FR4 epoxy board is the preferred material for insulation gaskets.

It should be noted that FR4 is not the material with the highest performance in all aspects. For example, polyimide (PI) has higher temperature resistance than FR4, but PI material is expensive. However, FR4 achieves an excellent balance between electrical insulation performance, mechanical strength, environmental resistance, and processing cost, resulting in extremely high overall cost-effectiveness, which is the key reason why it has become a mainstream choice.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer