Insulating Crepe Paper and Crepe Paper Pipes:In-depth Analysis

In the core components of power transmission, transformers, and high-voltage equipment, there exists a crucial type of component—insulating crepe paper and insulating crepe tubes. They are essential for the safe and stable operation of various electrical equipment. This article will provide a comprehensive analysis from aspects such as product definition, manufacturing characteristics, core performance, and application scenarios.

What are Insulating Crepe Paper and Insulating Crepe Pipes?

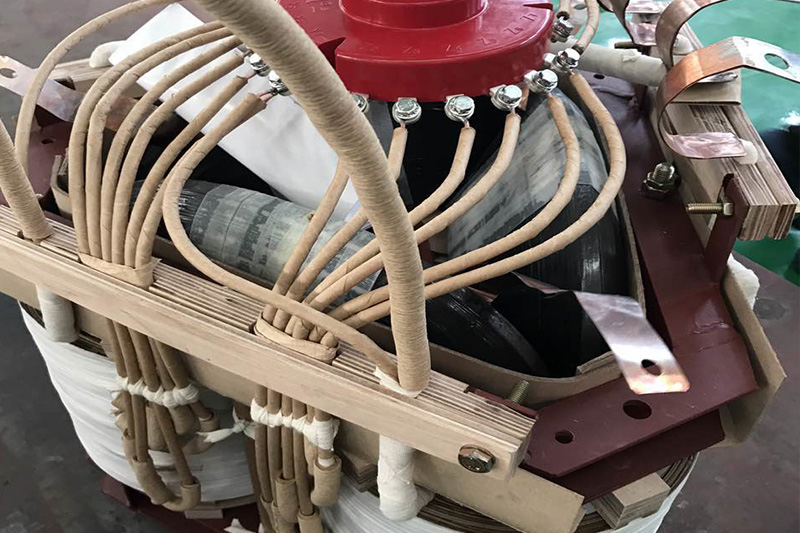

Insulating crepe paper is an insulating material made from cellulose as a base material through a special crepe-forming process. This crepe-forming process endows insulating crepe paper with flexibility, ductility, and high tensile strength. Compared to flat insulating paper, insulating crepe paper can adhere more tightly to the surface of irregular components such as wires and coils when wound, thus avoiding air gaps.

Insulating crepe pipes are composite structure insulating components. Their manufacturing process: first winding multiple layers of high-quality insulating crepe paper into a shape, then impregnating it with resin, and finally curing it through high-temperature baking to create a rigid cylindrical product. This composite structure gives insulating crepe tubes both excellent electrical insulation and mechanical strength.

Core Performance Advantages

♦ Extremely High Electrical Strength: They can withstand extremely high short-term and long-term voltage stress, effectively preventing breakdown.

♦ Excellent Flexibility and Adhesion: The wrinkled structure allows for stretching and compression, tightly adhering to the conductor, eliminating air gaps, and reducing partial discharge.

♦ Superior Mechanical Strength: The tear and tensile strength of crepe paper is far superior to ordinary insulating paper. Crepe paper tubes possess very high radial and axial mechanical strength.

♦ Excellent Thermal Stability: They Typically withstand temperatures from 105°C (Class A) to 220°C (Class C) and above for extended periods, depending on the impregnating resin.

♦ Low Dielectric Loss: They can help reduce energy loss and heat generation during equipment operation.

♦ Environmentally Friendly and Biodegradable: They are primarily composed of natural cellulose, and is environmentally friendly.

Application Scenarios: What are the core application areas?

1. Typical Applications of Insulating Crepe Paper

Insulating crepe paper is a thin insulating material with tensile and adaptability. Its main applications are concentrated in the following two aspects:

- Conductor Insulation: Insulating crepe paper is directly wound onto the surface of coil conductors in transformers, motors, and other equipment to form a basic insulation layer, effectively preventing short-circuit faults.

- Gap Filling: Filling the gaps between coils or conductors with insulating crepe paper makes the winding structure more compact, reducing vibration and displacement during equipment operation.

2. Core Uses of Insulating Crepe Paper Tubes

Insulating crepe paper tubes are rigid round tubes made by rolling and baking multiple layers of insulating crepe paper. They serve a dual function of structural support and insulation in equipment. Main applications include:

- Coil Support: Insulating crepe paper tubes act as support components for transformer and motor coils, and coils directly wound on them. They provide both structural fixation and insulation to ground.

– Lead Insulation Sleeve: By placing a crepe insulation paper tube over the conductive rod that passes through the transformer tank wall or other metal components, it prevents the rod from coming into contact with the metal parts, thereby avoiding ground faults.

- Internal Isolation Components: The insulating corrugated paper tube serves as an insulating partition or support cylinder inside the equipment, effectively separating and securing components at different potentials.

FAQs

Q1: Is there a moisture risk associated with crepe insulation paper tubes?

A1: The cellulose-based material of crepe insulation paper naturally has hygroscopic properties. However, after high-quality resin impregnation, the moisture resistance of the insulation crepe paper tube is significantly improved. Therefore, it is important to keep the storage and transportation environment dry.

Q2: What are the storage requirements for this type of insulation material?

A2: Crepe insulation paper and crepe paper tubes should be stored in a cool, dry, and well-ventilated indoor environment. They must be kept away from moisture, chemicals, and direct sunlight. It is recommended to keep the product in its original packaging.

Q3: What is the typical service life of crepe insulation paper?

A3: Its service life is influenced by multiple factors, including operating temperature, electrical stress, mechanical vibration, and environmental conditions. When used within design specifications, the lifespan of crepe insulation paper can match that of the equipment itself—often lasting several decades.

Q4: Are crepe insulation paper and crepe paper tubes customizable?

A4: Yes. Professional manufacturers can provide insulation crepe paper in various thicknesses, widths, and lengths, as well as crepe insulation tubes in different diameters, lengths, resin systems.

Crepe insulation paper and crepe insulation paper tubes are essential insulating materials in modern power industries. With their unique physical structure and excellent overall performance, they provide reliable insulation solutions for high-voltage electrical equipment. Whether for power transformers or instrument transformers, equipment manufacturers must understand the characteristics of these materials and select them correctly—this is key to ensuring product quality and operational safety.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer