Transformer Insulation Crepe Paper Tube

In the field of power transmission and distribution, the stable operation of transformers is fundamental to grid safety. Inside a transformer, the insulation crepe paper tube is a critical component. It forms part of the transformer’s insulation system and is key to ensuring efficient and long-term operation. This article explains the characteristics, applications, and industry role of transformer insulation crepe paper tubes to help you make the right selection.

What is an Insulation Crepe Paper Tube?

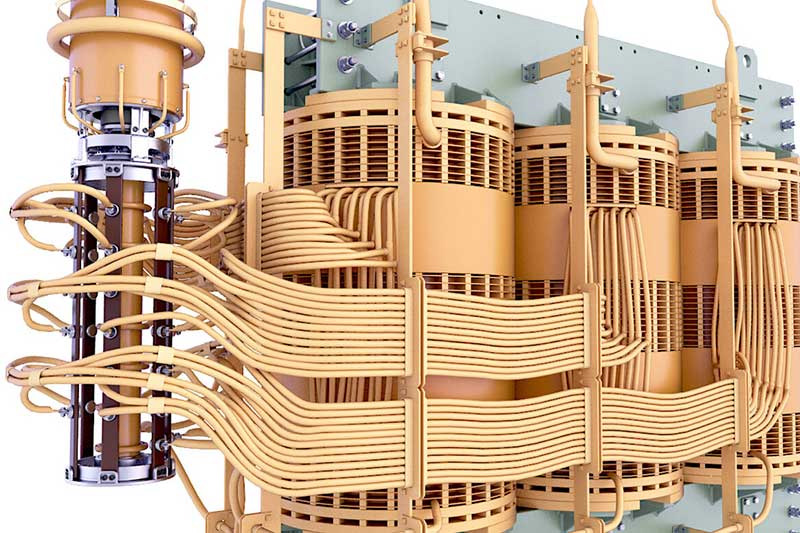

An insulation crepe paper tube is made from pure sulfate wood pulp or high-temperature-resistant materials such as NOMEX® paper, processed through a special creping technique. Its corrugated structure gives it flexibility, elongation, and mechanical strength. It can tightly fit around internal transformer conductors such as leads and tap changers, forming a stable insulation barrier.

Performance Advantages of Insulation Crepe Paper Tubes

1. Excellent Electrical Insulation Performance

Insulation crepe paper tubes offer high dielectric strength. They can withstand overvoltage and electric field stress during transformer operation, preventing turn-to-turn, layer-to-layer, and ground faults.

The uniform material and structure of crepe paper tubes help maintain a stable electric field distribution inside the transformer, reducing the risk of partial discharge.

2. Outstanding Mechanical and Physical Properties

The crepe structure of the insulation tube makes it easy to bend and install. It can adapt to the complex internal spaces of a transformer and remain dimensionally stable despite thermal expansion, contraction, and electromagnetic vibration.

It features high tear strength and tensile strength, making it resistant to damage during installation and operation, ensuring a long service life.

Its low density and high permeability facilitate the impregnation and circulation of transformer oil, ensuring effective cooling and stable insulation performance within the transformer system.

3. Superior Thermal Stability and Aging Resistance

High-quality insulation crepe paper tubes can withstand transformer oil and high-temperature environments for long periods. Their performance degrades slowly, supporting long-term transformer operation.

4. Environmentally Friendly and Safe

Insulation crepe paper tubes are mainly made from natural cellulose or eco-friendly synthetic materials. They are biodegradable or recyclable and meet environmental standards.

The crepe paper tube contains no harmful substances such as corrosive sulfur, which ensures it does not affect transformer oil quality.

Applications of Insulation Crepe Paper Tubes

1. Oil-Immersed Transformers

Insulation crepe paper tube is used for insulating wrapping of winding leads and tap changers. It can closely fit conductors to form an insulation barrier and adapt to thermal expansion, contraction, and electromagnetic vibration during operation.

Also, it is used for insulating and isolating core clamps and other structural components to prevent multi-point grounding faults.

2. Dry-Type Transformers

Crepe paper tubes made from high-temperature-resistant materials such as NOMEX® can be used as winding spacers and insulating blocks, helping form cooling air ducts and maintain insulation distances.

They also provide primary insulation for internal leads, ensuring safe operation in air-cooled environments.

3. Special Electrical Equipment

In reactors and instrument transformers, they are used for interlayer insulation, structural support, and conductor-bar insulation, helping withstand electromagnetic forces and ensuring measurement accuracy.

In the renewable energy sector (wind power, photovoltaic inverters), they are used in filter and smoothing reactors, and are capable of adapting to high-frequency and high-temperature operating conditions.

FAQs

Q1: What is the difference between insulation crepe paper tubes and ordinary paper tubes?

A1: Insulation crepe paper tubes are specially designed for electrical applications. They offer high dielectric strength, thermal stability, and mechanical toughness, and are manufactured through strict purification and drying processes. Ordinary paper tubes have no insulation properties and are prone to moisture absorption and aging.

Q2: What is the purpose of the “crepe” structure?

A2: The crepe structure increases the longitudinal elongation and radial flexibility of the insulation crepe paper tube, making it less likely to break during wrapping and installation. It also allows the tube to accommodate thermal expansion and contraction of conductors.

Q3: What should be considered when installing insulation crepe paper tubes?

A3: Ensure the installation environment is clean and dry to avoid contamination of the insulation crepe paper tubes. During wrapping, the tube should be wound tightly and evenly, without wrinkles or gaps. After installation, the transformer should undergo drying and vacuum oil-filling to remove internal moisture and ensure optimal performance of the insulation crepe paper tubes.

Contact us today to choose high-quality insulation crepe paper tubes for your transformer and ensure safe and reliable power operation.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer