What is Aramid Paper? A Comprehensive Analysis of its Performance, Applications, and Irreplaceability

In the field of high-tech materials, aramid paper is a high-performance material. It is widely used in high-end fields such as aerospace and electrical electronics. The following will provide a detailed explanation of its definition, performance, applications, and irreplaceability.

What is Aramid Paper?

Aramid paper is not made from traditional wood pulp, but rather as a nonwoven fabric material made from aromatic polyamide fibers. Nomex and Kevlar, developed by DuPont, are the most representative products among aramid fibers.

The production process of aramid paper involves using a special papermaking process to shape chopped aramid fibers and precipitated fibers. The final product combines the thinness of paper with the excellent properties of engineering plastics.

The performance characteristics of its core components are as follows:

- Meta-aramid: Excellent heat resistance, insulation, and flame retardancy.

- Para-aramid: High strength and tensile modulus.

Aramid paper combines the advantages of both fibers, forming unique structural characteristics.

Main Properties of Aramid Paper

The widespread application of aramid paper is based on its numerous excellent comprehensive properties, specifically as follows:

1. High Temperature Resistance and Flame Retardancy

Aramid paper can operate stably for extended periods in high-temperature environments above 200°C, and its short-term temperature resistance can exceed 300°C. It does not melt. When exposed to flame, it carbonizes to form a heat-insulating layer, and it self-extinguishes after being removed from the flame source, achieving a flame retardancy rating of UL 94 V-0. This property stems from the rigid structure of the aramid molecular chain, giving it a high glass transition temperature and thermal decomposition temperature.

2. Electrical Insulation Properties

Aramid paper maintains high dielectric strength and insulation resistance even in high-temperature and high-frequency environments. In contrast, the insulation performance of common insulating materials such as PET and PI films significantly decreases under high-temperature conditions. The stable chemical structure of aramid paper, and its ability to maintain its morphological integrity after carbonization, ensures its insulation reliability under harsh working conditions.

3. Mechanical Strength

Aramid paper has high tensile strength and tear strength, good toughness, and is not easily damaged. This performance is attributed to the reinforcing effect of para-aramid fibers, which form a stable reinforcing structure within the material.

4. Chemical Stability

Aramid paper resists the erosion of most organic solvents, oils, and lubricants, and ages slowly. Aramid itself is a highly stable polymer with natural resistance to chemical corrosion.

5. Insulation and Voltage Resistance

Aramid paper possesses excellent insulation properties and achieves high insulation levels without additional treatment. It can be used directly as insulation material for equipment such as motors and transformers.

6. Lightweight Properties

Aramid paper has a low density, and its use helps reduce the overall weight of equipment.

Main Application Scenarios of Aramid Paper

Aramid paper is widely used in the civilian power equipment sector, particularly in traction transformers, traction motors, drive motors, generators, and UHV transmission equipment used in rail transit, new energy vehicles, and wind power systems.

Compared with traditional cellulose-based insulation materials, aramid paper offers superior thermal resistance, weather resistance, safety performance, and load endurance, making it ideal for high-power and high-voltage electrical equipment.

It also helps reduce equipment size and weight while improving reliability under complex operating conditions.

|

End Application Field |

Specific Applications |

Function |

|

Transformers & Reactors |

Used as primary insulation material in UHV transformers, high-speed rail traction transformers, wind power transformers, photovoltaic power reactors, etc. |

Improves thermal resistance and insulation performance,and reduces equipment size and weight. |

|

Generators & Motors |

Main insulation for NEV motors, wind power generators, hydropower generators, thermal power generators, elevator motors, etc. |

Enhances overload capability and improves equipment adaptability and safety. |

|

Electrical Switches & Circuit Breakers |

Core insulation material for electrical switches and circuit breakers. |

Increases impact resistance of arc chambers and extends dynamic fatigue life and safety. |

|

Computer, Phone Batteries & PCBs |

Core material for mobile phone lithium batteries, laptop batteries, SMT substrates, and printed circuit boards. |

Enhances heat resistance of electronics and improves PCB signal transmission speed, strength, and quality. |

The Irreplaceability of Aramid Paper

Aramid paper is difficult to replace with other materials in key areas, primarily due to its unique combination of properties, specifically:

1. Combining High Temperature Resistance and High Insulation Performance

While materials like asbestos and ceramic fibers possess high temperature resistance, their mechanical strength or insulation properties are relatively poor. Ordinary plastic films and other insulating materials cannot operate for extended periods in environments above 200°C. Aramid paper is one of the few thin insulating materials that can maintain stable performance under high temperature (>200°C) and high voltage conditions.

2. A Balance of High Strength and Lightweight Properties

The aerospace industry has strict requirements on equipment weight. Aramid paper-based honeycomb core materials have high specific strength and specific modulus, which is an advantage unmatched by metallic materials.

3. Stable Safety and Reliability

The flame retardancy, low smoke, and non-toxicity of aramid paper are inherent to the material itself, not achieved by adding flame retardants. Therefore, its performance does not degrade with prolonged use or environmental changes, ensuring the safety of products such as aircraft and high-speed trains throughout their entire service life.

4. Excellent Processability and Multifunctionality

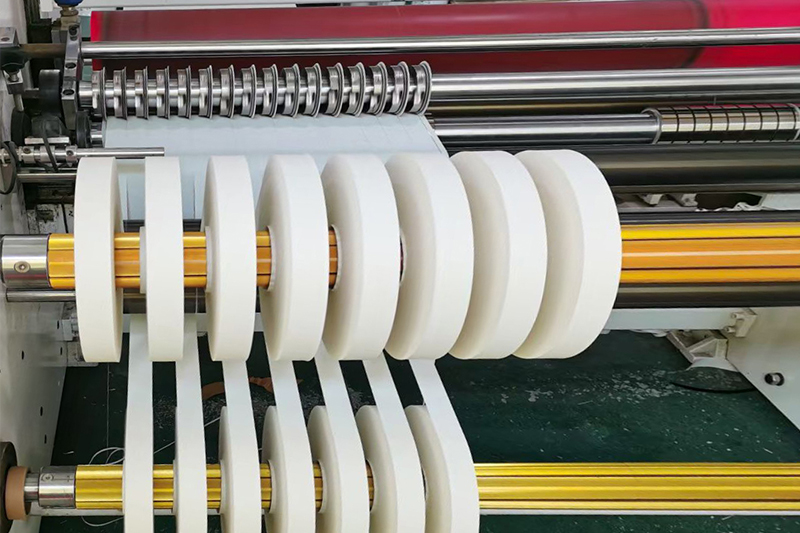

Aramid paper can be processed using processing methods of conventional paper such as stamping, cutting, folding, and winding, making it easy to form complex shapes. Furthermore, it can be laminated with materials such as resins and films to further enhance its performance.

With its unique raw material composition and processing, aramid paper possesses a combination of excellent properties, including high temperature resistance, high insulation, and high strength, playing an irreplaceable role in key fields such as power equipment and aerospace.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer