Laminated Wood and SMC: Transformer Insulation Blocks

Inside a power transformer, insulation blocks may be small in size, but they play an essential role. They must provide mechanical support to keep the windings firmly in place, while also offering excellent electrical insulation to ensure long-term, safe, and stable transformer operation. Laminated wood and SMC (Sheet Molding Compound) are two widely used and highly recognized materials for these insulation blocks. This article compares the two to help you make the right technical selection.

What Are Transformer Insulation Blocks?

Transformer insulation blocks are insulating components installed between windings and between the windings and the core. Their primary functions include:

Mechanical support: Withstand the electromechanical forces generated during short-circuit events and prevent deformation or displacement of internal components.

Electrical insulation: Maintain reliable insulation performance under high electric field conditions.

Forming cooling oil channels: Create paths for transformer oil circulation to ensure effective cooling.

Choosing the right insulation block material directly affects transformer performance, service life, and operational safety.

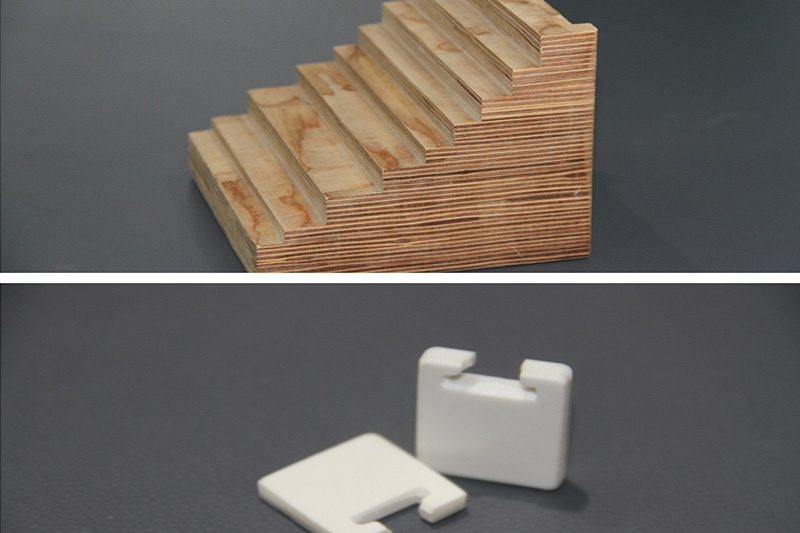

Laminated Wood Insulation Blocks

Laminated wood generally refers to specially processed densified laminated wood sheets. Using high-quality birch, beech, or similar hardwoods as raw materials, the wood veneers are impregnated with phenolic or epoxy resin and then pressed under high temperature and pressure to form a dense, high-strength insulating material.

1.Main Advantages

High mechanical strength: Excellent compressive and bending strength along the laminated direction, effectively resisting short-circuit forces.

Good dielectric properties: After resin impregnation, the material achieves high electrical insulation strength with stable performance.

Excellent oil absorption: Easily impregnated by transformer oil, enhancing insulation properties and ensuring good compatibility within the oil-immersed system.

Flexible machining: The laminated wood can be processed into various complex shapes and dimensions based on design requirements.

Environmentally friendly: The laminated wood is made from renewable resources with potential biodegradability.

2.Potential Drawbacks

Moisture absorption: Although resin-impregnated, it still requires moisture protection in extremely humid environments.

General consistency: As a natural material, slight variations may occur between batches.

3.Applications of Laminated Wood in Transformers

Laminated wood is mainly used in oil-immersed transformers (10 kV–35 kV), including:

♦ Coil support blocks

♦ Pressure plates, clamping rings, and fastening components

♦ Lead supports and winding spacers

♦ Core structure support parts

♦ Tie rods and mechanical reinforcement components

Its stable and reliable performance in oil makes laminated wood one of the most common support materials in oil-immersed transformers.

SMC Insulation Blocks

SMC (Sheet Molding Compound) is composed of unsaturated polyester resin, glass fiber, fillers, and various additives. It is formed through a molding process and cured at high temperature to produce a solid, durable component.

1.Main Advantages

Excellent dimensional stability: Extremely low moisture absorption ensures that dimensions and performance remain nearly unchanged even in humid environments.

Outstanding electrical properties: High insulation strength, low dielectric loss, and stable, consistent performance.

High strength and lightweight: Glass fiber reinforcement provides high mechanical strength while maintaining relatively low material density.

Strong design adaptability: Molding allows production of complex geometries with precise holes and slots, reducing assembly steps.

Consistency and suitability for mass production: Industrial-scale production ensures highly uniform performance and quality across batches.

2.Potential Drawbacks

Higher initial cost: Mold expenses make small-batch production more expensive than laminated wood.

Difficult repair: Damaged parts cannot be repaired on-site and require full replacement.

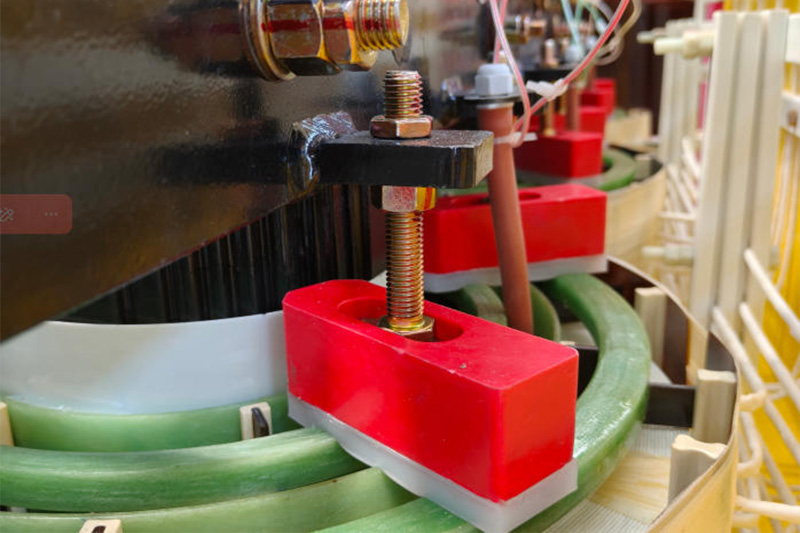

3.Applications of SMC in Transformers

SMC is widely used in dry-type transformers and other air-insulated equipment, including:

♦ Dry-type transformer insulation blocks

♦ Coil clamps and end-structure components

♦ High-temperature support components

♦ Insulation plates, clamping frames, and end supports

SMC is especially suitable in environments requiring high heat resistance, low moisture absorption, and high flame retardancy.

Why Choose Ztelecgroup?

As a professional manufacturer and supplier of electrical insulation materials, we have long supplied the following products:

♦ Laminated wood insulation blocks (custom sizes available)

♦ SMC insulation blocks and molded parts

♦ FR4, G10, G11, NHN, AMA, AHA and other insulation materials

♦ Epoxy tubes, insulating paperboard, insulating supports

We offer custom manufacturing, factory direct supply, and fast delivery services.

Whether it's new transformer production or equipment maintenance and replacement, we can provide stable and reliable insulation material solutions.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer