Upgrading Power Systems with 33 kV Oil-Immersed Power Transformers

Upgrading Power Systems with 33 kV Oil-Immersed Power Transformers: Key Technologies and Application Essentials

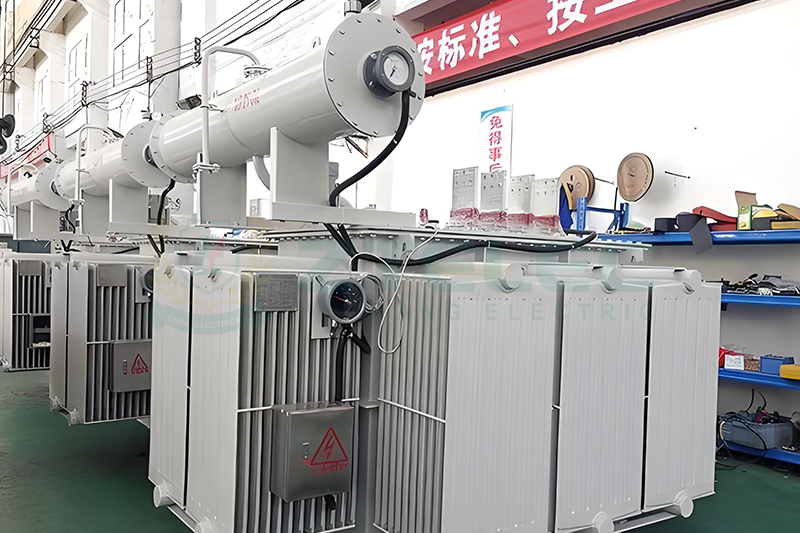

With the ongoing upgrade of global power grids, optimization of regional energy structures, and rapid advancement in industrial manufacturing, the 33 kV oil-immersed power transformer has become one of the core devices in medium-voltage transmission and distribution systems. Its high efficiency, strong insulation performance, excellent cooling capacity, and long service life provide superior performance compared to traditional transformer grades. This makes it ideal for industrial parks, regional substations, new energy projects, and urban distribution network renovation.

This article analyzes the essential technical advantages, structural design features, and typical application scenarios of 33 kV oil-immersed transformers to support engineering selection, procurement, and system planning.

Overview of 33 kV Oil-Immersed Power Transformers

Oil-immersed transformers use insulating oil for both cooling and insulation. Their main components include the transformer tank, insulating oil, iron core, and windings. This design provides stable operation, enhanced overload capability, and excellent thermal performance for medium-voltage applications.

Technical Advantages of 33 kV Oil-Immersed Transformers

High Efficiency and Low-Loss Performance

Advanced 33 kV oil-immersed transformers adopt high-grade cold-rolled silicon steel sheets and step-lap core structures, significantly reducing magnetization loss. Modern models achieve 30%–40% lower no-load loss compared with older transformer designs. New-generation products comply with IEC 60076 and GB 1094.1 energy-efficiency standards, reducing operational and lifecycle costs while supporting grid energy-saving goals.

Excellent Insulation and Cooling Capability

The insulation system integrates mineral insulating oil with insulation paper and uses vacuum impregnation to ensure high dielectric strength suitable for 33 kV operation. Cooling options include corrugated tanks, radiator fins, and forced oil circulation systems, enabling stable temperature control even during long-term high-load operation. The design also supports short-term overloads, ensuring adaptability to grid load fluctuations.

High Reliability and Long Service Life

Thanks to fully sealed tank structures, 33 kV oil-immersed transformers effectively prevent oil oxidation and moisture intrusion. They perform reliably in humid, dusty, or corrosive environments. With a typical service life of 25–30 years, they require less maintenance than dry-type transformers and provide strong mechanical stability.

Core Structural Design Features of 33 kV Transformers

Advanced Core Structure

Most 33 kV oil-immersed transformers use laminated or wound core constructions with low vibration and noise, making them suitable for urban substations. Their optimized magnetic paths reduce core loss and improve energy efficiency.

High-Quality Windings and Conductor Materials

Copper windings provide higher conductivity and strong short-circuit withstand capability, while aluminum windings offer cost-effective solutions for general applications. Common winding structures include frame, helical, and interleaved cylindrical configurations, each designed to improve mechanical stability and thermal performance.

Optimized Tank and Radiator Design

Tank structures include corrugated-wall and plate-radiator designs. Corrugated tanks require no periodic maintenance and are ideal for compact urban areas. Plate radiators provide larger heat-dissipation areas and can be equipped with cooling fans for forced oil circulation when needed.

Integrated Protection and Monitoring System

The transformer is equipped with a full protection package including gas relay, pressure relief valve, winding temperature controller, oil level gauge, and thermometer. These features support automatic protection, early fault detection, and remote monitoring.

Typical Application Scenarios of 33 kV Oil-Immersed Transformers

Regional Substations (Primary Step-Down Hubs)

One of the most common applications is regional substations receiving power from 110 kV or 66 kV transmission networks. The 33 kV transformer reduces the voltage and supplies it to 10 kV distribution feeders or large industrial users, ensuring stable regional power distribution.

Large Industrial Parks

High-energy-demand industries such as steel, chemical production, cement plants, and automotive manufacturing rely on 33 kV transformers to stabilize internal power supply. The transformer steps down the grid’s 33 kV voltage to 10 kV or 6.3 kV for plant production lines, large motors, and distribution systems.

Renewable Energy Power Plants

In wind farms, 33 kV transformers collect the electrical output from multiple turbines and transmit it to the grid via 33/110 kV or 33/220 kV step-up transformers. In photovoltaic power plants, the transformer steps up inverter outputs (e.g., 0.8 kV) to 33 kV for grid connection. Their stable performance supports long-term renewable energy operations.

The 33 kV oil-immersed power transformer plays a critical role in today’s medium-voltage distribution systems. With strong insulation, high efficiency, long service life, and flexible structural configurations, it is widely used in urban distribution networks, renewable energy integration, industrial energy supply, and regional substations. Understanding its technical characteristics and application benefits allows engineers and procurement personnel to optimize system reliability and energy performance.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer