Do you understand the specific classifications of cable paper?

Cable paper is a core category of electrical insulation materials. It is widely used in the production of power cables, communication cables, and special cables. For cable manufacturers, transformer factories, and power engineering companies, understanding the specific classifications and application differences of cable paper helps in scientific selection, cost optimization, and product quality improvement. This article will systematically outline the main classifications of cable paper, helping readers fully grasp the application characteristics of this material.

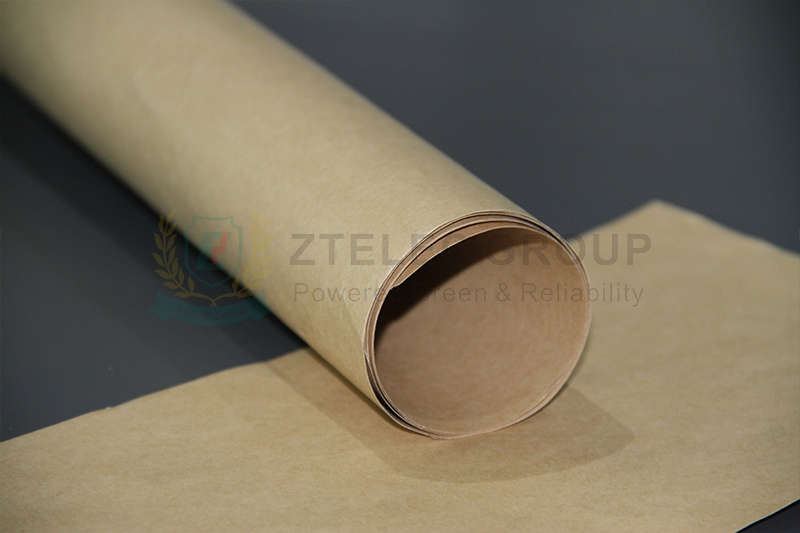

Overview of Cable Paper

Cable paper, also known as insulating paper, is a special paper product made from cellulose fibers. It is mainly used as the insulation layer and outer sheath of wires and cables. This material possesses excellent insulation properties and can withstand high temperatures, high pressures, and mechanical stress. It ensures the stable operation of cable lines and extends the service life of cables.

Functions of Cable Paper

The core functions of cable paper are:

It isolates the cable line from external environmental interference, preventing cable leakage, short circuits, and other faults.

It enhances the mechanical strength and tensile properties of cables, preventing cable breakage.

Cable paper also possesses moisture-proof, corrosion-proof, oxidation-resistant, and high/low temperature resistance properties, improving the reliability and service life of cables.

Specific Classifications of Cable Paper

1. Classification by Application

►Power Cable Paper

This is the most widely used type of cable paper. It is mainly suitable for oil-immersed high-voltage and ultra-high-voltage power cables.

Features:

High dielectric strength

Low dielectric loss

Dense fiber structure

Excellent oil impregnation performance

Typical applications:

10kV–500kV oil-immersed power cables

HVDC cable systems

►Communication Cable Paper

This type of cable paper is mainly used in traditional communication cables, control cables, and other low-voltage or weak-current systems.

Features:

Good flexibility

Uniform thickness

Suitable for multi-core wrapping structures

Typical applications:

Control cables

Signal and communication cables

2. Classification by Thickness Specifications

Cable paper is usually classified by basis weight or thickness. Different thicknesses correspond to different voltage levels and cable structure design requirements. Common thickness ranges:

Thin cable paper: 0.05–0.08 mm

Medium thickness cable paper: 0.08–0.13 mm

Thick cable paper: 0.13 mm and above

Selection recommendations: High-voltage cables are recommended to use multi-layer thin paper wrapping. For applications requiring high mechanical strength, the paper thickness can be appropriately increased.

3. Classification by Processing and Performance Grade

►Ordinary Cable Paper

It meets the insulation requirements of conventional cables and has a lower cost. It is suitable for standard operating conditions.

►High-Purity Cable Paper

This type of cable paper has extremely low impurity and metal ion content, resulting in excellent partial discharge performance. It is more suitable for high-voltage and ultra-high-voltage cable systems.

4. Classification by Impregnation Process Compatibility

►Oil-Impregnated Cable Paper

It is specifically designed for mineral oil or synthetic insulating oil systems. It has strong oil absorption, and its oil-paper composite insulation structure has stable performance.

►Special medium compatible cable paper

This type of cable paper is compatible with environmentally friendly insulating oil or special insulating media. It is often used in new and customized cable systems.

Key Considerations in Cable Paper Selection

♦ Electrical performance: dielectric strength, dielectric loss, volume resistivity

♦ Mechanical properties: tensile strength, elongation, flexibility

♦ Thermal performance: heat resistance class, thermal stability

♦ Environmental adaptability: moisture resistance, chemical corrosion resistance, weather resistance

♦ Safety: flame-retardant properties, non-toxic and environmentally friendly characteristics

Cable paper is not a single-category material, but a specialized insulation product with multi-dimensional classification standards and distinct technical characteristics. Different types of cable paper emphasize different aspects, such as voltage compatibility, mechanical strength, and oil impregnation performance.

For cable manufacturers and power engineering applications, a clear understanding of cable paper classification standards and scientific material selection is a critical prerequisite for ensuring the safe, stable, and long-term operation of power systems.

- more+releated article

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass

- 2026-01-29Ten Core Reasons to Choose Oil-Immersed Transf

- 2026-01-29Epoxy FR4 yellow board in power transformer