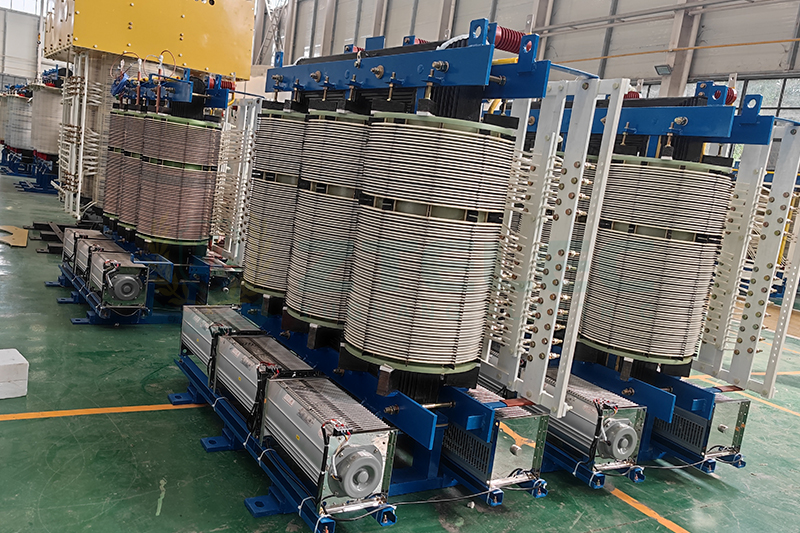

High-Power 12-Pulse Low-Harmonic Phase-Shifting Rectifier Dry-Type Transformer – Energy-Saving and Reliable Power Solution

In modern industry, power quality and efficiency are vital for maintaining reliable operation and reducing energy waste. The 12-pulse phase-shifting rectifier dry-type transformer is a key solution for achieving these goals. Designed for high-power DC systems, it effectively minimizes harmonic distortion, improves power factor, and enhances overall energy efficiency—making it ideal for electrochemical, metallurgical, and automation industries.

What Is a 12-Pulse Phase-Shifting Rectifier Dry-Type Transformer?

This transformer is engineered specifically for rectifier loads such as frequency converters, electrolysis, DC drives, and plating systems. It uses two sets of three-phase secondary windings with a 30° phase shift, each powering a 6-pulse rectifier bridge. The DC outputs from both bridges are combined to form a smooth 12-pulse DC output with significantly lower harmonic distortion.

Core Features

Phase-Shifting Function: By adopting special winding structures such as the extended delta connection, the transformer achieves precise phase-shifting, which is essential for eliminating harmful harmonics.

Dry-Type Design: The transformer uses epoxy resin casting or vacuum pressure impregnation (VPI) technology to ensure flame resistance, explosion protection, and pollution-free operation. It is ideal for indoor environments requiring high fire safety standards.

12-Pulse Rectification: Compared to conventional 6-pulse rectification, 12-pulse rectification significantly lowers harmonic currents on the input side, improving overall power quality and grid stability.

Advantages of the 12-Pulse Energy-Saving Design

1. Reduced Harmonic Pollution: Harmonics can cause equipment malfunctions, cable overheating, and reduced efficiency. The 12-pulse configuration eliminates 5th and 7th harmonics, reducing THDi from around 30% (in 6-pulse systems) to below 10–15%. This ensures smoother operation and longer equipment life.

2. Significant Energy Savings: By minimizing harmonic currents, the transformer reduces reactive power losses and line losses, increasing system efficiency. It also improves power factor, helping users avoid utility penalties and even qualify for energy-efficiency incentives. Advanced magnetic design and high-quality materials further reduce no-load and load losses.

3. High Reliability and Safety: Dry-type transformers eliminate risks of oil leakage and fire hazards, making them suitable for underground facilities, subways, and high-rise buildings. Their compact structure, strong insulation, and excellent heat dissipation ensure reliable performance even under fluctuating load conditions.

Core Application Scenarios

The 12-pulse phase-shifting rectifier dry-type transformer is widely used in industries requiring high-quality DC power and low harmonic distortion, including:

• Industrial variable frequency drives (VFDs) for large motors, pumps, and compressors.

• Electrochemical and metallurgical industries such as electrolysis, electroplating, and metal refining.

• DC drive systems for steel rolling mills, mining hoists, and heavy machinery.

• Data centers and hospitals needing stable, low-distortion power for UPS systems.

• Laboratories and test platforms requiring pure and stable DC power.

How to Choose the Right 12-Pulse Rectifier Transformer

When selecting a transformer, confirm key technical parameters with your supplier:

• Rated power (kVA): Based on DC load requirements.

• Input/output voltage: Must match your grid and rectifier equipment.

• Phase-shift angle: Typically ±7.5°, ensuring a 30° total phase difference.

• Insulation class: F or H, depending on temperature and service conditions.

• Protection class (IP rating): Chosen based on installation environment.

• Compliance standards: Ensure conformity with IEC, IEEE, or GB standards.

While the initial cost of a 12-pulse high-power phase-shifting rectifier dry-type transformer may be higher than that of standard units, its long-term advantages—energy savings, lower maintenance, and reduced harmonic impact—make it a highly cost-effective solution. Over its service life, it delivers measurable returns through reduced downtime, improved power quality, and compliance with modern energy efficiency standards.

Contact us today to get a customized high-efficiency, low-harmonic rectifier transformer solution tailored to your industrial power needs.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele