Vehicle Drive Systems

With the rapid development of the electric vehicle industry in recent years, drive motor technology has also made significant breakthroughs. Electric vehicles place stringent demands on drive motors, including high speed, high power density, lightweight design, miniaturization, and high reliability. Against this backdrop, high-performance insulation materials have become a key foundation for improving motor reliability and power density, and a crucial support for the continued development of advanced motor technologies such as high-frequency, high-voltage, high-temperature, and internal oil-cooled motors.

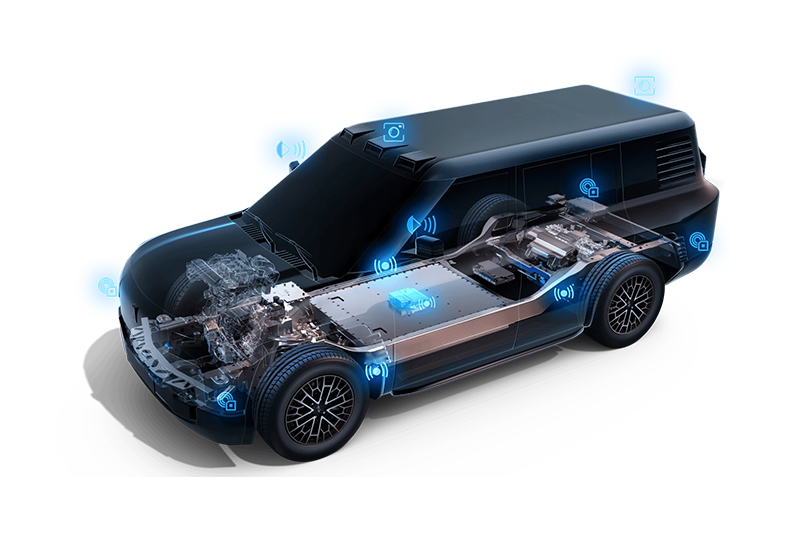

Electric vehicles, which use electricity as their primary power source, mainly include core components such as the battery and management system (BMS), drive motor and control system, vehicle management system (VMS), and the vehicle body. Among these, the motor, as a key power component of new energy vehicles, directly impacts the green and sustainable development of the entire industry through technological innovation.

Currently, motor technology is advancing comprehensively towards permanent magnetization, high speed, oil-cooled flat wire, integration, miniaturization, lightweighting, high efficiency, and high power density, and has achieved a series of significant advancements. In the motor insulation stage, the core objective is to achieve reliable isolation between conductors and between conductors and the iron core through high-performance insulation materials.

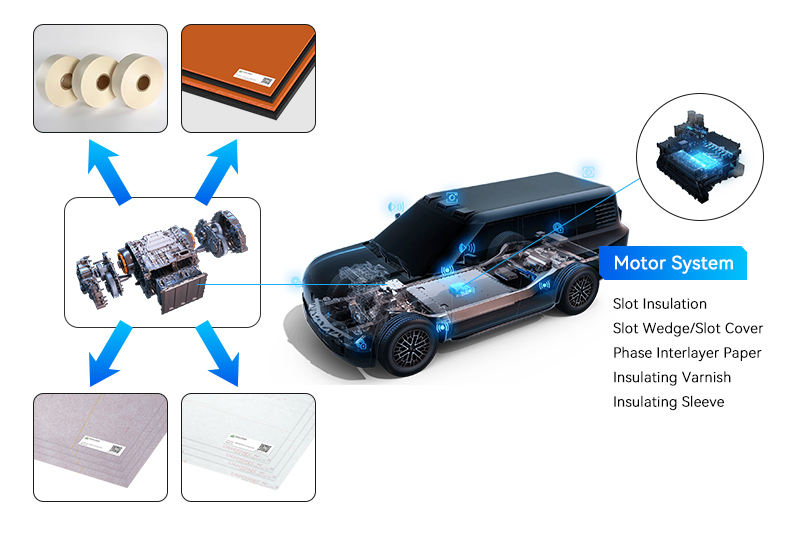

XUJUE ELECTRICAL has established a significant market position in the field of motor insulation materials thanks to its comprehensive product portfolio and rapid response to new market demands:

- Its products employ a multi-layered composite structure design, giving them excellent thermal, mechanical, and chemical stability while maintaining a high breakdown voltage.

- To adapt to more demanding application environments, its products are continuously optimized for resistance to non-volatile organic compounds (NSN) and active cooling agents (ATF), improving partial discharge resistance in 800V high-voltage systems and further enhancing thermal conductivity.

XUJUE ELECTRICAL will continue to dedicate itself to providing high-quality insulation solutions for the new energy vehicle industry, contributing to the iterative upgrading of motor technology and driving the entire industry forward.

Insulation Materials for Vehicle Drive Systems

1.Slot Insulation, Turn-to-Turn Insulation, and Phase-to-Phase Insulation Materials

NOMEX Aramid Paper, NHN Composite Paper, NMN Composite Paper, etc.

2.Slot Wedge Insulation Materials

Fiberglass Board, Bakelite Board, Composite Paper

3.Lead Wire Insulation Materials

Insulating Sleeves

4.Coil Binding Materials

NOMEX Paper, Binding Wire

Table Summary:

|

Application Location |

Insulation Materials |

|

Slot Insulation, Turn-to-Turn Insulation, and Phase-to-Phase Insulation |

NOMEX Aramid Paper, NHN Composite Paper, NMN Composite Paper, etc. |

|

Slot Wedge Insulation |

Fiberglass Board, Bakelite Board, Composite Paper |

|

Lead Wire Insulation |

Insulating Sleeves |

|

Coil Binding |

NOMEX Paper, Binding Wire |

- more+releated article

- 2026-01-28Application of Epoxy Pultruded Rods in Insulat

- 2026-01-27Transformer Production Process: Step-by-Step M

- 2026-01-27FR4 Material Density: Standard Values and Tole

- 2026-01-27Main Types of Power Transformers and Their App

- 2026-01-26Black Core FR4 Material Properties and Applica

- 2026-01-23Understanding 1000 kVA Oil Filled Transformer

- 2026-01-23G10 Solar Panel Back Sheet Price

- 2026-01-23What Is an Oil-Filled Self-Cooled Transformer

- 2026-01-22G10 Solar Panels Suppliers | Bulk Procurement

- 2026-01-22How to Select Power Transformers for High-Rise