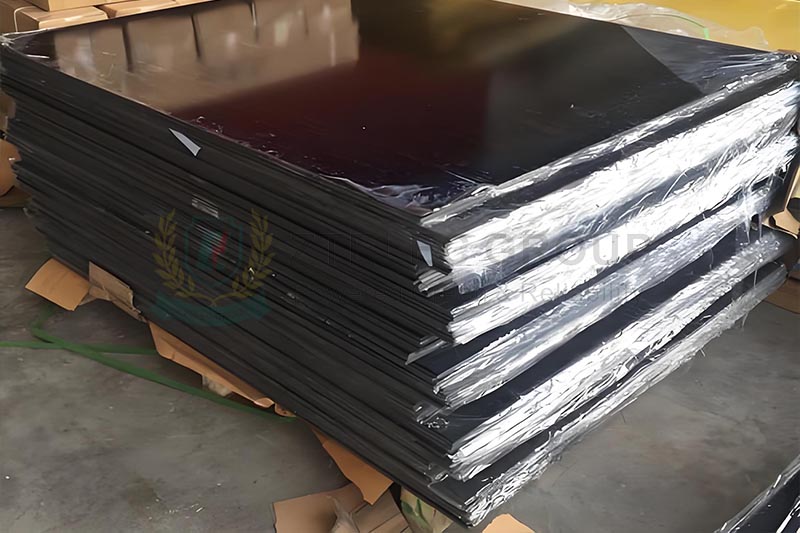

Black Core FR4 Material Properties and Applications

With the rapid development of the power equipment, electronics manufacturing, and new energy industries, the market demand for high-performance insulation materials continues to grow. Black Core FR4 material is a modified epoxy glass fiber laminate with stable electrical properties, good mechanical strength, and a unique appearance. It has been widely used in mid-to-high-end industrial and electrical insulation fields. This article will systematically introduce the performance characteristics and typical application scenarios of Black Core FR4 material.

What is Black Core FR4 Material?

Black Core FR4 is based on standard FR4 epoxy glass fiber laminate. Through optimized formulation or process adjustment, the core layer exhibits a uniform black color. It retains the original flame retardant rating and electrical properties of FR4, while offering superior appearance consistency, processing stability, and structural recognizability. It is suitable for applications requiring high quality and reliability.

Core Performance Advantages of Black Core FR4 Material

1. Excellent Thermal Management and Heat Dissipation Capabilities

Black Core FR4 typically incorporates special fillers and optimized resin formulations, significantly improving thermal conductivity.

2. Enhanced Mechanical Strength and Dimensional Stability

Black core FR4 exhibits excellent Z-axis thermal expansion coefficient through improved resin system and optimized reinforcing materials. This reduces stress during temperature cycling, improving the reliability of multilayer boards.

3. Excellent Electrical Performance Consistency

Special fillers in the black core layer reduce local fluctuations in dielectric constant, ensuring uniform signal transmission. It is suitable for high-speed digital circuits and high-frequency applications.

4.Improved Chemical Resistance and Moisture Resistance

The modified resin formulation enhances the material's resistance to chemical corrosion and moisture, extending its lifespan in harsh environments.

5.Aesthetic Value and Practical Functionality

The dark appearance not only provides a professional and aesthetically pleasing visual effect but also reduces light reflection, offering practical functional advantages in certain optical and display applications.

Typical Applications of Black Core FR4

1. Electrical Insulation

Insulation components for low-voltage and medium-voltage power distribution equipment

Insulation partitions for switchgear and circuit breakers

Structural components for relays and contactors

2. Transformers and Power Equipment

Internal insulation supports for dry-type transformers

Coil pads and insulation strips

Structural supports and protective components

3. PCB and Electronics Industry

Structural supports for industrial control boards

Electronic components with stringent material consistency requirements

Insulation base plates for power electronic equipment

4. New Energy and Industrial Equipment

Insulation components for photovoltaic inverters

Structural insulation components for energy storage systems

Electrical isolation components for automation equipment

Key Considerations for Selecting Black Core FR4

1. Material Specifications

Glass transition temperature (Tg): Typically not lower than 150°C

Dielectric constant (Dk) and loss factor (Df): Requires selection based on frequency requirements

Thermal conductivity: Evaluated in conjunction with heat dissipation requirements

Withstand voltage and insulation resistance: Ensures safe operation

2. Cost-Benefit Analysis

Black core FR4 typically costs 15%-30% more than standard FR4, but its advantages in reliability, performance, and lifespan offset the initial cost difference, making it suitable for high-end applications.

3. Manufacturing Process Compatibility

Most black core FR4 materials are compatible with standard PCB manufacturing processes, requiring only minor adjustments to drilling, lamination, and surface treatment parameters for production adaptation.

Black core FR4 material retains the advantages of traditional FR4, with superior consistency and reliability, meeting the demands of modern power and electronic equipment for high-quality insulation materials. It is suitable for transformers, electrical equipment, new energy, and other fields, offering a balance of performance and stability.

Get Black Core FR4 Material Quotes and Technical Support!

If you need stable, uniformly high-quality black core FR4 insulation material for transformers, electrical equipment, or industrial electronics applications, we can provide standard specifications or customized solutions. Please contact us for detailed technical parameters, sample support, and quotations. Our engineering team will provide professional advice based on your application scenario.

- more+releated article

- 2026-01-26Black Core FR4 Material Properties and Applica

- 2026-01-26Main Types of Power Transformers and Their App

- 2026-01-23Understanding 1000 kVA Oil Filled Transformer

- 2026-01-23G10 Solar Panel Back Sheet Price

- 2026-01-23What Is an Oil-Filled Self-Cooled Transformer

- 2026-01-22G10 Solar Panels Suppliers | Bulk Procurement

- 2026-01-22How to Select Power Transformers for High-Rise

- 2026-01-21Transformer-Specific Electrical Laminated Wood

- 2026-01-20High-Quality EPGC308 Epoxy Fiberglass Insulati

- 2026-01-20Detailed Explanation of Specifications, Rating