Understanding 1000 kVA Oil Filled Transformer Prices: Key Cost Factors Explained

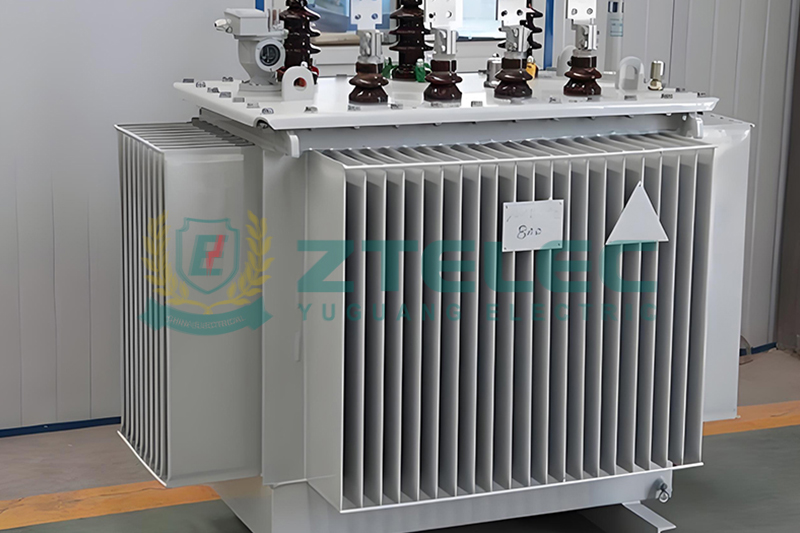

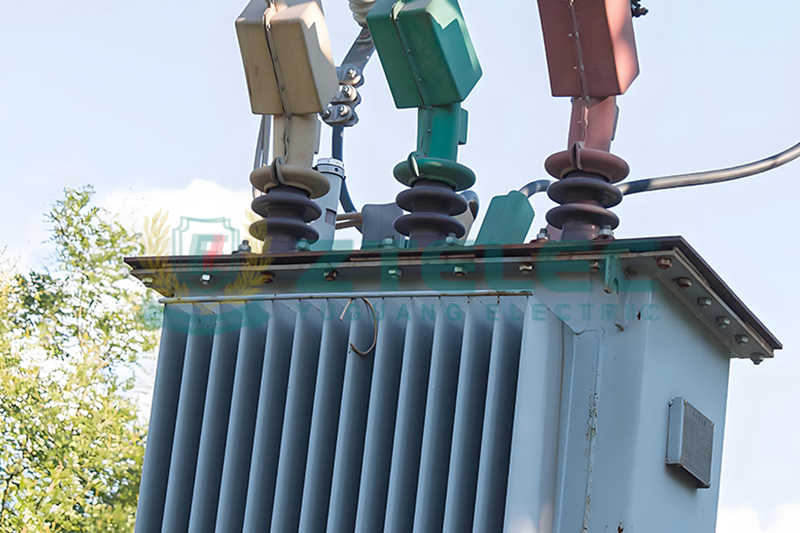

The 1000 kVA oil filled transformer is widely used in medium to large-scale power distribution systems, including industrial plants, commercial centers, renewable energy facilities, and utility substations. As a higher-capacity unit, it serves as a critical link between medium-voltage networks and end-user loads.

Due to its larger size and higher power handling capability, the 1000 kVA oil filled transformer price is influenced by a broader range of technical and market factors compared with smaller ratings. Understanding these factors is essential for accurate budgeting and informed procurement decisions.

Capacity Scaling and Electrical Design Complexity

At the 1000 kVA level, transformer design must account for higher current levels, increased thermal stress, and stricter mechanical requirements. Voltage ratio configuration, impedance specification, and insulation coordination significantly affect winding layout and material usage.

Higher short-circuit forces at this capacity require reinforced winding structures and improved mechanical support, increasing both design complexity and manufacturing cost.

Core Loss Optimization and Efficiency Requirements

Core losses represent a major component of lifetime operating cost for 1000 kVA oil filled transformers. To meet efficiency regulations and reduce long-term energy consumption, manufacturers often use premium-grade grain-oriented silicon steel.

Optimized core joint design and precision cutting techniques improve magnetic performance but raise production costs. For continuously energized installations, these investments can deliver substantial energy savings over time.

Conductor Material and Thermal Performance

Copper windings are commonly specified for 1000 kVA transformers due to their superior conductivity and mechanical strength. Copper improves thermal performance and enhances short-circuit withstand capability, which is critical at higher capacities.

Aluminum windings may still be used in certain cost-driven projects, but careful thermal and mechanical design is required to ensure long-term reliability. The price difference between copper and aluminum configurations becomes more pronounced at this capacity level.

Insulation System and Oil Selection

The insulation system of a 1000 kVA oil filled transformer must withstand higher electrical and thermal stress. High-quality insulating oil, combined with robust solid insulation materials, is essential for reliable operation.

In applications with enhanced safety or environmental requirements, ester-based insulating fluids may be adopted. These fluids increase initial cost but provide improved fire resistance and environmental performance.

Cooling Design and Load Capability

Standard ONAN cooling is widely used for 1000 kVA transformers, but thermal design margins are often more conservative due to higher load density. Larger radiators and optimized oil circulation paths are required to control temperature rise.

Enhanced cooling design increases material usage and fabrication complexity, directly affecting transformer pricing.

Standards, Testing, and Project Specifications

Compliance with IEC, ANSI, or utility-specific standards significantly influences the 1000 kVA oil filled transformer price. Higher impulse withstand levels, extended routine testing, and special acceptance criteria increase production and testing costs.

Projects involving power utilities or critical infrastructure may require additional documentation, factory inspections, or type tests, further impacting pricing.

Market Trends and Supply Chain Factors

Global demand for medium and high-capacity transformers has increased alongside grid modernization and renewable energy integration. This demand growth, combined with raw material price volatility, contributes to fluctuating transformer prices.

Transportation costs and delivery lead times also play a larger role at the 1000 kVA level due to increased weight and size.

Long-Term Performance and Investment Value

For high-capacity transformers, long-term reliability and efficiency are often more important than initial purchase price. Reduced losses, stable thermal performance, and strong after-sales support contribute to lower total ownership cost.

When evaluated over its service life, a properly specified 1000 kVA oil filled transformer can deliver consistent performance and predictable operating costs.

- more+releated article

- 2026-01-23Understanding 1000 kVA Oil Filled Transformer

- 2026-01-23G10 Solar Panel Back Sheet Price

- 2026-01-23What Is an Oil-Filled Self-Cooled Transformer

- 2026-01-22G10 Solar Panels Suppliers | Bulk Procurement

- 2026-01-22How to Select Power Transformers for High-Rise

- 2026-01-21Transformer-Specific Electrical Laminated Wood

- 2026-01-20High-Quality EPGC308 Epoxy Fiberglass Insulati

- 2026-01-20Detailed Explanation of Specifications, Rating

- 2026-01-19Dry-Type Transformer Model Comparison Analysis

- 2026-01-16DDP Diamond Dotted Paper Supplier | Custom &am