What Are the Different Grades of FR4 Epoxy Board?

FR-4 is a widely used flame-retardant composite material grade designation in the electronics industry. Its core definition refers to a resin-based composite material that can self-extinguish under combustion conditions. Rather than a single material, FR-4 is a composite system made from tetrafunctional epoxy resin combined with fillers and glass fiber, pressed under specific manufacturing processes. It plays a critical role in the insulation structures of TVs, monitors, new energy equipment, aerospace systems, and more. Below is a breakdown of the grade differences of FR4 epoxy boards from multiple dimensions.

Classification by Flame-Retardant Grade (Based on UL94 Standard)

Flame retardancy is one of the core properties of FR-4. According to the UL94 standard, FR-4 materials are graded in ascending order as HB, V-2, V-1, and V-0. Each level has specific requirements and corresponding application scenarios:

1. HB Grade – Basic Flame Retardancy

The material must meet the following burn rate limits:

For specimens 3–13 mm thick: Burn rate must be less than 40 mm/min

For specimens under 3 mm: Burn rate must be less than 70 mm/min, or the flame must extinguish before reaching the 100 mm mark

This type of FR4 epoxy board is suitable for applications with low flame-retardant requirements, such as temporary insulation structures or non-critical electrical components—for example, simple internal linings of enclosures or partitions in low-power devices.

2. V-2 Grade – Intermediate Flame Retardancy

After two 10-second exposures to open flame, the flame must extinguish within 60 seconds.

Minor flaming drips are allowed during the test.

This grade of epoxy board is commonly used for internal insulation in general electrical equipment, such as insulation pads for low-voltage switchgear or winding insulation structures in standard electric motors.

3. V-1 Grade – Enhanced Flame Retardant Safety

After undergoing two 10-second open flame tests, the flame must extinguish within 60 seconds, and no flaming particles are allowed to drip.

This type of epoxy board is suitable for electrical housings or structural components with higher flame-retardant safety requirements, such as insulation support plates in household appliances or internal insulation layers in small control cabinets.

4. V-0 Grade – The Highest Level of Flame Retardancy

After two 10-second flame exposure tests, the flame must be extinguished within 30 seconds, with no flaming particles falling off.

Typical models include G11, JC833, and JC834. These epoxy boards are used in safety-critical components, such as insulation boards for new energy vehicle battery packs, insulation layers for high-voltage connectors, and core insulation structures in aerospace equipment.

Classification by Model and Core Performance

Different models of FR-4 epoxy boards exhibit significant differences in flame retardancy, heat resistance, mechanical strength, and environmental performance. Below is an analysis of commonly used models and their characteristics:

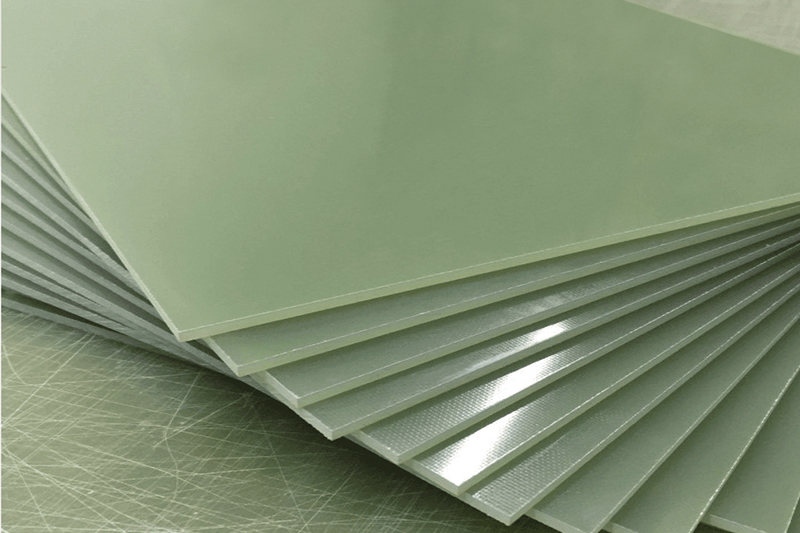

1. G10 Epoxy Board

Flame Retardant Grade: UL94 V-2

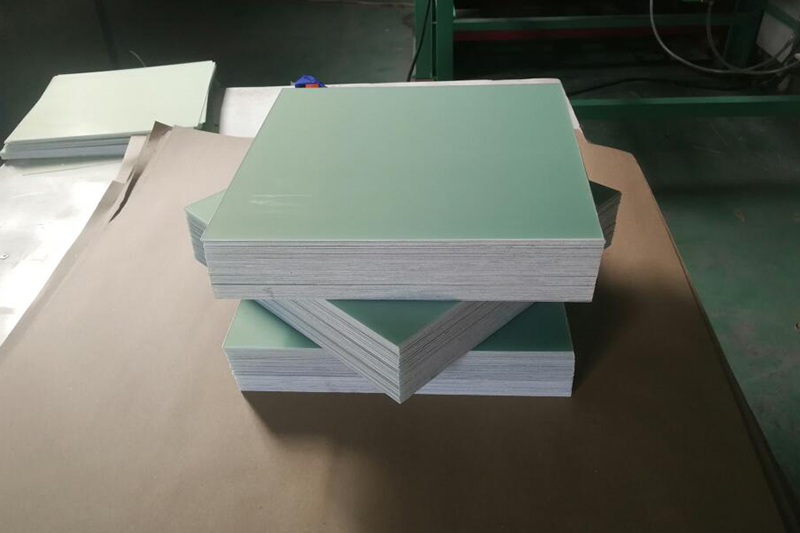

Appearance: Light green

Features: Halogen-free formulation with excellent environmental performance, dielectric breakdown voltage > 60 kV.

Typical Applications: Insulation partitions in switchgear, transformer insulation components, linings for explosion-proof electrical enclosures, and other environmentally sensitive applications

2. G11 Epoxy Board

Flame Retardant Grade: UL94 V-0

Temperature Resistance: Short-term tolerance up to 228°C

Features: Stable electrical performance in both dry and humid conditions, high mechanical strength.

Typical Applications: High-voltage switch insulation structures, electrical insulation components in extreme temperature and humidity environments.

3. JC833 / JC834 Epoxy Boards

Flame Retardant Grade: UL94 V-0

Density: 1.8–2.0 g/cm³

Features: High machining precision and mechanical stability.

Typical Applications: Precision-machined parts (e.g., planetary gears), insulation boards in aircraft and high-speed trains, and core insulation parts in transformers.

Classification by Dielectric Performance (for High-Frequency Applications)

Dielectric constant (Dk) and dielectric loss (Df) are key indicators of signal transmission performance in FR-4 epoxy boards. Based on these parameters, FR-4 materials can be categorized as follows:

Standard FR-4: It is suitable for low-frequency circuits with conventional signal transmission needs, such as power supply boards, general digital circuits, and motherboards in household electronic devices.

Low Dielectric FR-4: It offers better signal integrity and is primarily used in high-frequency signal transmission applications, including RF modules, 5G base station RF units, and small radar front-end circuits.

Ultra-Low Loss FR-4: It delivers performance comparable to PTFE materials but at a lower cost. This type of epoxy board is ideal for high-speed digital circuits (e.g., server motherboards), millimeter-wave radar, and high-frequency communication devices where minimizing signal loss is critical.

From the above classification, it can be seen that the grade classification of FR-4 epoxy boards needs to be comprehensively considered in combination with flame retardant requirements, performance parameters and application scenarios. When making a selection, it is necessary to match the specific safety standards, environmental conditions and signal transmission requirements of the equipment.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele