CNC Precision G11 Machined Components

In high-end manufacturing, precision is a key factor affecting product quality. As a representative product of CNC precision machining, G11 machined components, with their excellent dimensional stability, reliable mechanical properties, and superior machining characteristics, are widely used in medical devices, optical instruments, and high-precision electronic equipment. This article will systematically introduce the technical characteristics and application scope of G11 machined components and explain how to select a suitable supplier.

What are CNC Precision G11 Machined Components?

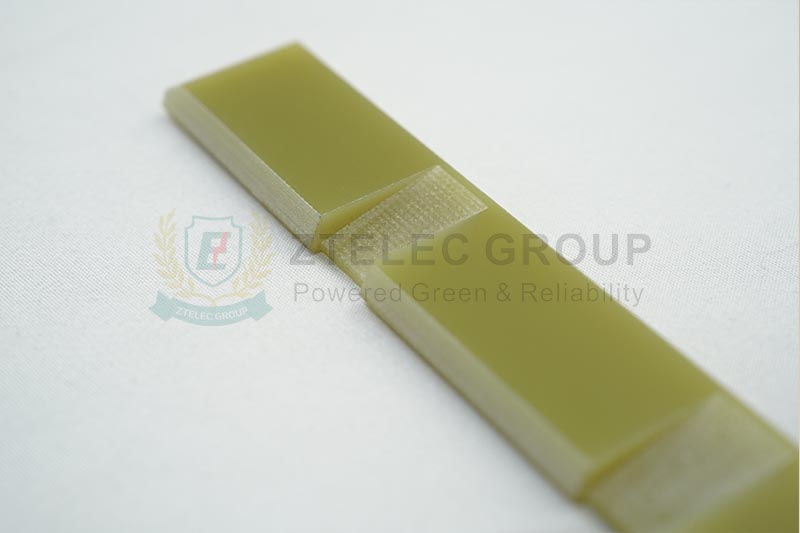

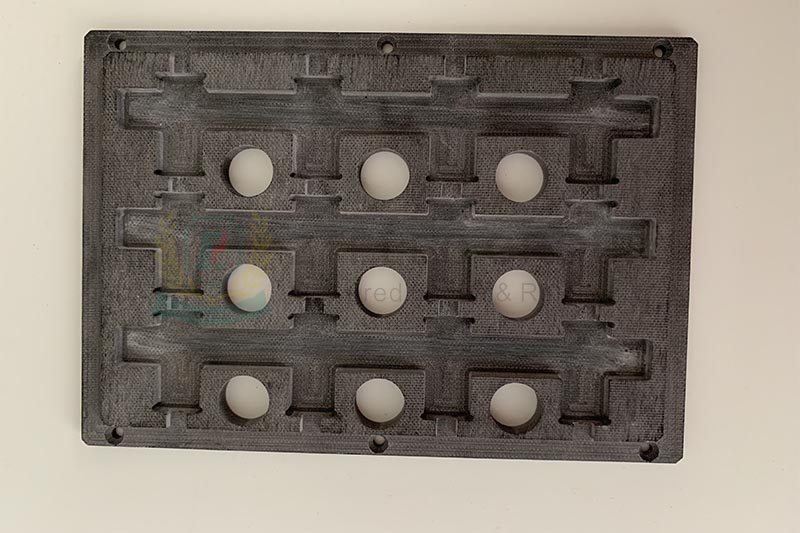

G11 is a glass fiber reinforced epoxy resin laminate material that conforms to the NEMA G11 standard. Its heat resistance is superior to that of G10 material.

Through precision machining processes such as CNC milling, drilling, tapping, and precision cutting, G11 sheets can be manufactured into various high-precision insulating structural components, mainly including:

Insulating supports

High-temperature partitions

Insulating pads

Positioning structural components

Special-shaped insulating parts

CNC machining ensures the consistency of component dimensions, making it suitable for mass production and high-reliability applications.

Key Characteristics of G11 Material

1.Excellent Dimensional Stability

Low coefficient of thermal expansion, maintaining dimensional stability even with temperature changes.

Extremely low moisture absorption, preventing dimensional deviations caused by humidity variations.

2.Reliable Mechanical Properties

High strength and stiffness, suitable for manufacturing structural support components.

Good fatigue resistance, helping to extend component lifespan.

Good wear resistance, reducing equipment maintenance frequency and costs.

3.Electrical and Chemical Properties

Excellent electrical insulation properties and high dielectric strength.

Resistant to most chemicals and solvents, suitable for a wide range of environments.

Meets UL94 V-0 flame retardant rating, ensuring high safety.

Advantages of CNC Precision Machined G11 Components

Compared to traditional machining methods such as ordinary cutting and molding, CNC precision machining offers the following advantages in manufacturing G11 insulating components:

High dimensional accuracy and precise tolerance control.

Capable of machining complex structures and irregularly shaped parts, adapting to diverse needs.

Smooth and even component edges, free from defects such as delamination and burrs.

High batch consistency makes it suitable for OEM manufacturing and bulk production needs in various engineering projects.

These characteristics are particularly important for systems with stringent assembly precision requirements, such as transformers, motors, and power equipment.

Typical Applications of CNC G11 Machining Components

1.Dry-type Transformers and Reactors:

Winding Supports, End Plates, High-Temperature Phase-to-Phase Separators

2.Motors and Power Generation Equipment:

Insulation Structure Supports, Positioning and Isolation Components, Vibration-resistant Insulation Components

3.Medium and High Voltage Switchgear:

Insulation Brackets, Circuit Breaker Internal Insulation Components, Busbar Supports

4.New Energy and Power Electronics:

Energy Storage System Insulation Structure Components, Inverter and Frequency Converter Internal Insulation Components, E-house and Modular Power Station Supporting Insulation Components

Common G11 CNC Machining Processes

Depending on the product structure and precision requirements, G11 machining typically employs the following processes:

CNC Precision Milling (can machine planes, slots, complex contours, etc.)

Drilling/Tapping (for installation and fixing)

Precision Cutting and Chamfering (improves assembly safety)

Custom Machining (produced according to drawings)

How to Choose a High-Quality G11 Machined Component Supplier?

1.Technical Capability Assessment

Examine the supplier's CNC equipment level (e.g., whether they have a 5-axis machining center).

Understand the supplier's practical experience and technical expertise in material handling.

Evaluate their quality control system and relevant certifications (e.g., ISO9001, AS9100).

2.Service and Support

Whether it has the ability of engineering design and technical support.

Their responsiveness to sample development and small-batch production.

The quality assurance measures during mass production.

3.Supply Chain Reliability

The sourcing and quality assurance of raw materials.

The stability of delivery cycles.

The comprehensiveness of after-sales technical support.

As the manufacturing industry demands increasing product precision and reliability, G11 materials, due to their performance characteristics, will play a crucial role in more high-end fields. Choosing a machining supplier with professional technology, advanced equipment, and strict quality control is key to ensuring the full performance of G11 components.

If your equipment operates in high-temperature, high-voltage, or environments with stringent reliability requirements, CNC precision G11 machined components can serve as an ideal insulation material solution.

Please feel free to contact us for technical support, material selection advice, and customized quotations.

- more+releated article

- 2026-01-30Encapsulated and Cast-Coil Cast-Resin Transfor

- 2026-01-30CNC Precision G11 Machined Components

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo

- 2026-01-29EPGC308 Epoxy Sheet — Electrical Insulation

- 2026-01-29Applications of EPGC203 Insulation Epoxy Glass