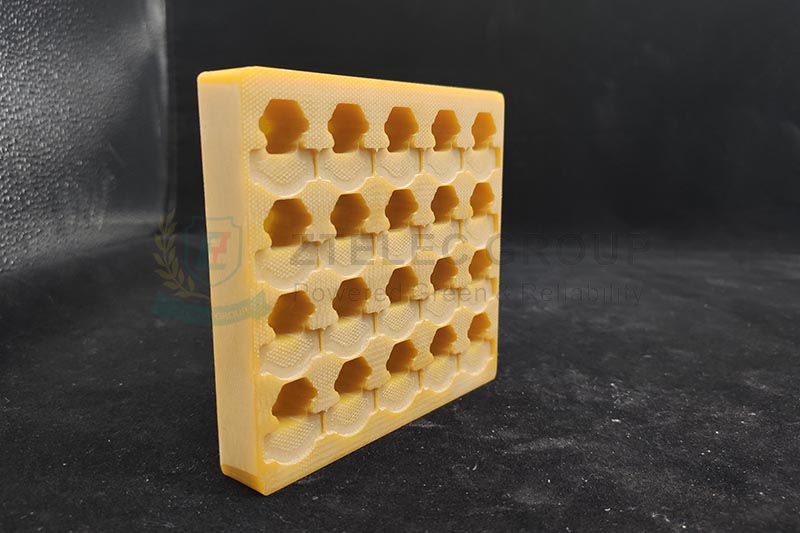

G11 Epoxy Fiberglass Machined Parts | High-Temperature Insulation

In fields such as power electronics, rail transportation, and high-end industrial equipment, the high-temperature, high-load operating environment places stringent requirements on the performance of insulation materials. G11 epoxy fiberglass laminate (also known as G11 epoxy board), as a high-performance industrial insulation material, has become a commonly used material in high-temperature insulation applications due to its excellent heat resistance, mechanical strength, and stable electrical properties. This article will explain the characteristics, applications, and key processing techniques of G11 epoxy machined parts.

G11 Insulation Material Overview

G11 epoxy fiberglass material is a rigid sheet material made by impregnating fiberglass cloth with epoxy resin and then laminating and curing it under high temperature and pressure. This material belongs to the "G10/G11" series in the NEMA standard, where G11 specifically refers to the category that can maintain good mechanical properties under high-temperature environments.

Key Characteristics of G11 Epoxy Fiberglass Parts: High-Temperature Insulation Performance

1.High Heat Resistance

G11 epoxy machined part exhibits the following heat resistance characteristics:

Long-term operating temperature: Not lower than 155℃ (Class F grade)

Short-term withstand temperature: Up to 180℃

Under high-temperature operating conditions, G11 material is not prone to softening, delamination, or carbonization, making it suitable for high-temperature insulating structural components.

2. Stable Electrical Insulation Performance at High Temperatures

In high-temperature environments, G11 epoxy machined part maintains the following electrical properties:

High dielectric strength

Low dielectric loss factor (good Dk/DF stability)

Good arc resistance and tracking resistance

These characteristics enable G11 epoxy machined parts to effectively isolate conductors in high-temperature electric fields, preventing insulation breakdown and aging.

3. Excellent Mechanical Strength at High Temperatures

While most insulating materials soften and lose strength at high temperatures, G11 epoxy machined part exhibits the following characteristics:

High retention of flexural and compressive strength at high temperatures

Good creep resistance

Structural dimensional stability under long-term loads

This is of great significance for insulating supports that simultaneously bear electrical and mechanical loads.

4. Good Thermal Stability and Aging Resistance

G11 machined part possesses the following characteristics in terms of thermal stability and aging resistance:

Long thermal aging life

Unrestricted cracking under temperature cycling conditions

Unrestricted from powdering or delamination during long-term use

In equipment requiring continuous operation, such as transformers and motors, using G11 epoxy machined part helps extend the service life of the insulation system.

Applications of G11 Epoxy Fiberglass Machining Parts

Motors and Transformers:

G11 machined part is used as slot wedges, insulating partitions, end supports to ensure insulation safety in high-temperature environments.

Power Equipment:

Suitable for insulating structural components in switchgear, circuit breakers, instrument transformers, etc.

Electronics and Semiconductors:

G11 machined part can be used to manufacture high-temperature test fixtures, PCB support boards, insulating carriers, etc.

Industrial Equipment:

Used for insulation protection in high-temperature environments such as hot presses, drying equipment, and high-temperature furnaces.

Key Machining Processes for G11 Parts

To ensure reliable performance of G11 parts in high-temperature insulation applications, the following aspects should be noted during machining:

Precision Cutting and CNC Machining: Control dimensional accuracy, maintain smooth edges, and avoid delamination and burrs.

Drilling and Tapping: It is recommended to use carbide tools to reduce wear on the tools caused by the fiberglass.

Surface Treatment: Polishing, chamfering, or spraying can be performed as needed.

Quality Inspection: Includes dimensional inspection, electrical performance testing (such as withstand voltage testing), and temperature resistance testing to ensure product compliance.

With its high temperature resistance, high insulation, and excellent mechanical properties, G11 epoxy fiberglass components have become important insulation components in various high-temperature, high-reliability applications. Proper material selection, precision machining, and rigorous quality testing are key to ensuring long-term stable operation.

If you require custom-made insulation parts with high temperature resistance and high strength, we can provide G11 material selection and precision machining services.

Please feel free to contact us for technical consultation and quotations.

- more+releated article

- 2026-01-31G11 Epoxy Fiberglass Machined Parts | High-Tem

- 2026-01-312000 kVA Copper Oil Filled Transformer: Featur

- 2026-01-30Encapsulated and Cast-Coil Cast-Resin Transfor

- 2026-01-30CNC Precision G11 Machined Components

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo