G10 Machined Parts Manufacturer | High-Temperature Resistant Insulation Processing Parts

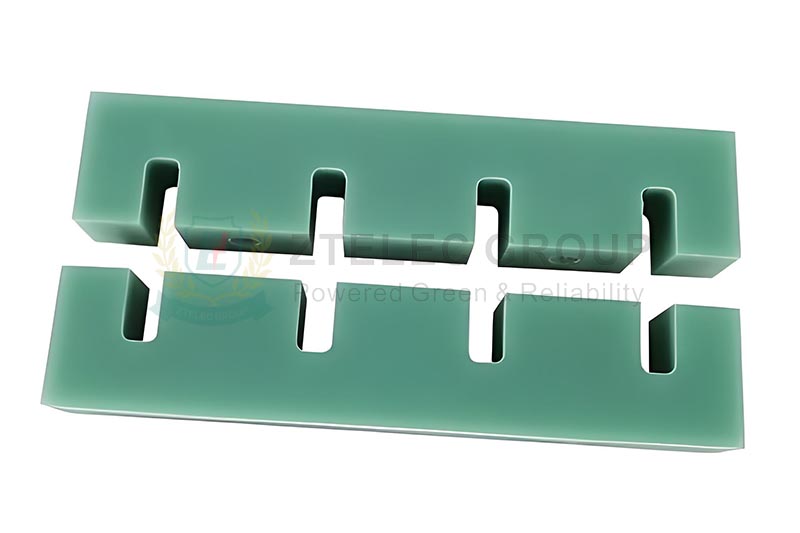

In fields such as power equipment, industrial automation, new energy, and rail transportation, the operational safety and service life of equipment are directly related to the stability and temperature resistance of insulation components. G10 insulation processing parts, as a glass fiber reinforced epoxy material, possess excellent electrical properties, high mechanical strength, and stable temperature resistance, making them suitable for demanding insulation applications.

This article will systematically introduce how professional G10 insulation component manufacturers provide reliable high-temperature resistant insulation processing part solutions to customers, covering aspects such as material characteristics, processing capabilities, typical applications, and selection points.

G10 Insulation Material Overview

G10 is a laminated composite material with epoxy resin as the matrix and glass fiber cloth as the reinforcement. It conforms to international standards such as NEMA G10/IEC 60893.

This material maintains stable performance during long-term use, thus finding wide application in medium and high voltage electrical equipment.

Main Characteristics of High-Temperature Resistant G10 Insulation Processing Parts

High-Temperature Resistance

This material can withstand long-term operating temperatures above 130°C and can withstand even higher temperatures in short periods. It maintains stable insulation strength and mechanical properties even in high-temperature environments.

High Mechanical Strength and Stiffness

G10 insulating parts have a high strength-to-weight ratio, strong impact and bending resistance, and good dimensional stability. They are suitable for load-bearing or support structures.

Good Electrical Insulation

Under humid and high-temperature conditions, G10 insulating parts maintain high insulation resistance and dielectric strength, ensuring the safe operation of electrical equipment.

Chemical Resistance and Moisture Resistance

G10 insulating parts have good resistance to most solvents, oils, and acidic/alkaline substances, and have low water absorption. They maintain stable performance in various environments.

Easy to process

These insulating parts are suitable for CNC precision machining, cutting, drilling, and grinding processes, and can be manufactured into insulating parts of various complex shapes.

Typical Applications of G10 High-Temperature Insulation Components

1. High and Low Voltage Switchgear

Busbar Supports

Insulating Partitions

Brackets and Fixing Structures

2. Transformers and Reactors

Coil Supports

Structural Insulation Components

High-Temperature Area Isolation Components

3. Motors and Industrial Equipment

Slot Wedges, End Insulation Components

High-Strength Insulation Support Components

New Energy and Rail Transit

Energy Storage System Insulation Structure Components

Traction System Insulation Components

Our Core Competencies as a Professional G10 Insulation Component Manufacturer

We not only provide materials, but also focus on precision manufacturing and service, specifically reflected in:

Strict Material Selection:

We use G10/FR-4 base materials from well-known domestic and international brands to ensure consistent and reliable material performance.

Precision Machining:

We are equipped with CNC machining centers, precision engraving machines, laser cutting machines, etc., to ensure that part dimensions, surface finish, and hole accuracy meet drawing requirements.

Comprehensive Quality Control:

From material warehousing and processing to finished product inspection, we implement comprehensive quality monitoring and use professional tools to test key dimensions and insulation performance.

Extensive Industry Experience:

We are familiar with the needs of various industries and can provide material selection advice and design optimization to help customers improve performance and control costs.

Flexible Customization:

We support prototyping and mass production based on drawings or samples to meet the customization needs of standard parts or complex structural components.

How to Choose a Reliable G10 Insulation Parts Manufacturer?

It is recommended to evaluate suppliers from the following aspects:

♦ Whether they accurately understand technical requirements and can provide professional recommendations

♦ Whether they have a complete and effective quality management system

♦ Whether the products comply with relevant international standards such as IEC and NEMA

♦ Whether they possess mature and reliable CNC machining capabilities

♦ Whether they can ensure stable quality and consistency for mass production

♦ Whether they support custom design and sample confirmation

An experienced G10 insulation parts manufacturer not only delivers qualified products, but also helps customers reduce system operating risks.

If you are looking for a technically reliable, quality-stable, and service-oriented G10 insulation parts manufacturer, we can support your high-temperature insulation machining requirements.

Feel free to contact us for customized solutions!

- more+releated article

- 2026-02-03G10 Machined Parts Manufacturer | High-Tempera

- 2026-02-03How to Choose a 1000 kVA Compact Substation: D

- 2026-02-03Cast-Resin Transformers: Encapsulated and Cast

- 2026-02-032000 kVA Copper Oil Filled Transformer: Featur

- 2026-02-03Encapsulated and Cast-Coil Cast-Resin Transfor

- 2026-02-03Low-Voltage Dry-Type Distribution Transformers

- 2026-02-02Customized G11 Insulating Machined Parts: Proc

- 2026-01-31G11 Epoxy Fiberglass Machined Parts | High-Tem

- 2026-01-30CNC Precision G11 Machined Components

- 2026-01-29What are composite insulation materials and ho