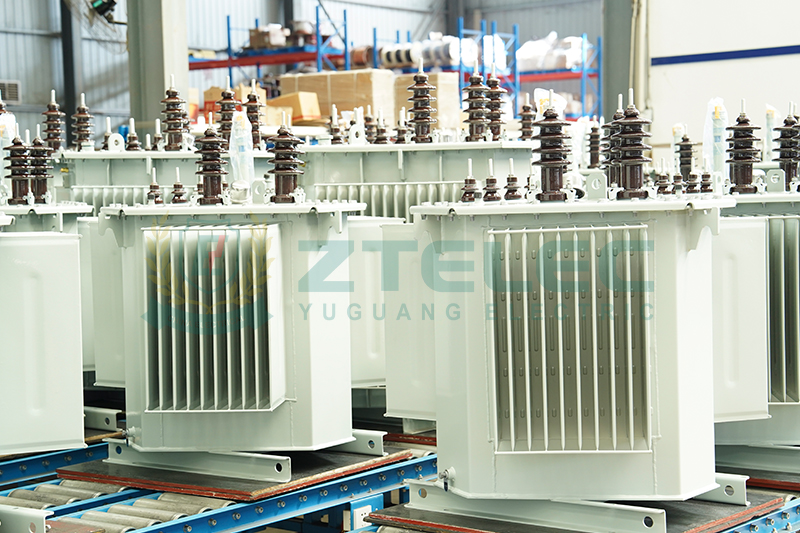

2000 kVA Copper Oil Filled Transformer: Features and Substation Applications

The 2000 kVA copper oil filled transformer is a widely adopted solution in medium-voltage power distribution systems and industrial substations. Known for stable performance, efficient heat dissipation, and long service life, this transformer type is commonly installed in factory substations, urban distribution networks, renewable energy facilities, and various infrastructure projects.

This article provides a comprehensive overview of the 2000 kVA copper oil filled transformer, focusing on its structural design, performance characteristics, and typical substation application scenarios.

Overview of the 2000 kVA Copper Oil Filled Transformer

A 2000 kVA copper-winding oil filled transformer uses mineral insulating oil as both the cooling and insulation medium. The windings are manufactured from high-purity electrolytic copper, offering excellent electrical conductivity, thermal stability, and mechanical strength. This design ensures reliable operation under continuous load conditions and occasional overloads.

Typical technical parameters of a 2000 kVA copper oil filled transformer include a rated capacity of 2000 kVA. Common high-voltage ratings are 6 kV, 10 kV, 11 kV, 20 kV, and 35 kV, while the low-voltage side is usually 0.4 kV and can be customized if required. The cooling method is ONAN or ONAF, with frequency options of 50 Hz or 60 Hz. The insulation system generally meets Class A or higher standards.

Key Features of a 2000 kVA Copper Oil Filled Transformer

Copper Winding Design for High Efficiency

Copper windings feature lower electrical resistivity than aluminum, which significantly reduces load losses and improves overall efficiency. The strong mechanical properties of copper also allow the transformer to withstand short-circuit forces and short-term overload conditions, enhancing operational safety and durability.

Oil Filled Cooling System for Reliable Heat Dissipation

The insulating oil performs dual functions by providing dielectric insulation and effective cooling. Heat generated during operation is transferred to the oil and dissipated through natural or forced circulation. Mineral insulating oil offers high dielectric strength, ensuring dependable insulation for both the windings and the core.

Rational Structure and Comprehensive Protection

The transformer core is typically made from cold-rolled silicon steel sheets, which help reduce no-load losses and operating noise. The sealing system may adopt a fully sealed structure or an oil conservator design, minimizing contact between oil and air and slowing oil aging. Standard protection devices include pressure relief valves, temperature indicators or controllers, and gas relays, providing multiple layers of operational safety.

Voltage regulation is usually achieved through on-load or off-load tap changers, with common adjustment ranges of ±2 × 2.5% or ±5%, allowing stable voltage output under varying load conditions.

Excellent Performance Parameters

A 2000 kVA copper oil filled transformer typically achieves operating efficiency above 98.5%, with some designs exceeding 99%. Both no-load and load losses comply with applicable energy efficiency standards, such as GB 20052. Operating noise is generally controlled below 65 dB, making the transformer suitable for installations near residential or commercial areas. Low voltage regulation rates further contribute to stable and reliable power supply.

Substation Applications of 2000 kVA Copper Oil Filled Transformers

Industrial Distribution Substations

In industrial environments such as manufacturing plants, mining operations, metallurgy, and chemical facilities, the 2000 kVA copper oil filled transformer is commonly used as a main distribution transformer. It supplies power to both production equipment and auxiliary systems, while its strong overload capacity accommodates fluctuating industrial loads and supports continuous operation.

Urban Power Distribution Networks

These transformers are widely deployed in urban medium-voltage distribution systems, including ground-level, semi-underground, and prefabricated substations. They are also used in box-type substations serving commercial complexes and large residential communities. Their mature design and long-term stability make them suitable for unattended operation, helping utilities reduce maintenance costs.

New Energy and Infrastructure Substations

In renewable energy projects such as wind farms and photovoltaic power plants, as well as data centers and transportation infrastructure, 2000 kVA copper oil filled transformers are often installed on the low-voltage side of step-up substations or used in auxiliary power systems. They provide reliable power support for both temporary and permanent installations.

Thanks to reliable operation, high energy efficiency, and strong adaptability, the 2000 kVA copper oil filled transformer remains a key component in modern power systems. With ongoing technological improvements and intelligent upgrades, this transformer type continues to meet growing demands for efficiency, reliability, and sustainability.

When selecting oil filled transformers for substation projects, it is recommended to consider technical parameters, operating conditions, and economic factors comprehensively. For customized configurations and detailed technical support, please consult professional manufacturers to obtain solutions tailored to your specific application requirements.

- more+releated article

- 2026-01-312000 kVA Copper Oil Filled Transformer: Featur

- 2026-01-31G11 Epoxy Fiberglass Machined Parts | High-Tem

- 2026-01-30Encapsulated and Cast-Coil Cast-Resin Transfor

- 2026-01-30CNC Precision G11 Machined Components

- 2026-01-29What are composite insulation materials and ho

- 2026-01-29NHN vs. AHA Insulation: Key Differences and Wh

- 2026-01-29Comparing NHN and AHA Insulation Paper in Moto

- 2026-01-29The Impact of NHN and AHA Insulation Paper on

- 2026-01-29The Role of NMN and AMA Insulation Paper in El

- 2026-01-29Applications of NMN Insulation Paper in Low-Vo