What is the g10 made of and the manufacturing process

2024-08-19 10:25 | By: ZTELEC-www.ztelecgroup.com | 150click

What is G10?

G10 is a composite material, meaning it is made up of multiple components to create a product that has desirable properties not found in the individual materials. The "G" in G10 stands for "glass," reflecting the material's composition of woven fiberglass cloth and epoxy resin.G10 is a high-pressure fiberglass laminate, a material often used in the manufacture of knife handles, circuit boards, and other items requiring a durable, moisture-resistant material.

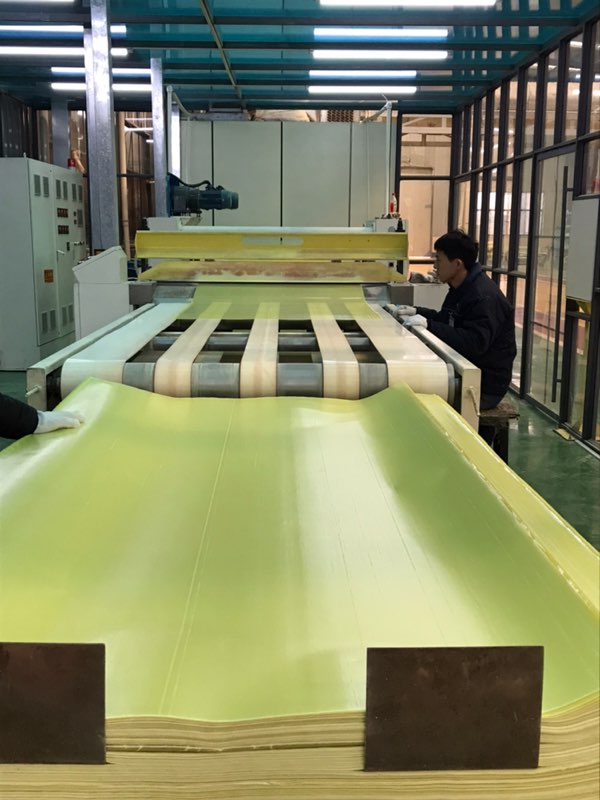

How G10 is Made

Electrical insulation materials G10: Manufacturing Process

Fiberglass Cloth Preparation:

The first step in the creation of G10 involves weaving glass fibers into a cloth. The glass fibers used in G10 are extremely fine, usually around 10 microns in diameter, which gives the material its strength and durability.

Epoxy Resin Application:

The woven fiberglass cloth is then impregnated with an epoxy resin. This resin is what binds the fibers together and gives the material its rigidity and resistance to moisture.

Layering:

Multiple layers of the resin-coated fiberglass cloth are stacked together. The number of layers depends on the desired thickness of the final product.

Curing Under Pressure:

The stacked layers are then subjected to high pressure and heat, which causes the resin to cure and bond the layers into a single solid piece. This process also removes any air bubbles, ensuring a strong, uniform material.

Cutting and Shaping:

After the curing process is complete, the G10 is cut into sheets of various sizes and thicknesses. These sheets can then be further shaped and finished as needed for specific applications.

Properties of G10

Strength and Durability: G10 is known for its high strength-to-weight ratio, making it extremely durable while remaining lightweight.

Moisture Resistance: The epoxy resin used in G10 is highly resistant to moisture, making the material ideal for use in environments where water exposure is a concern.

Electrical Insulation: G10 is an excellent electrical insulator, which is why it is often used in the manufacture of circuit boards and other electrical components.

Versatility: G10 can be easily machined, drilled, and shaped, making it a versatile material for a variety of applications.

tags:

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele