Dry-Type Transformer Production Line: Production Steps and Key Equipment

With the rapid growth of urban power distribution, renewable energy systems, rail transit, industrial automation, and data centers, dry-type transformers have become a core component of medium- and low-voltage power systems. Their advantages in fire safety, environmental protection, low maintenance, and operational reliability make them widely adopted in modern electrical infrastructure.

For both manufacturers and project purchasers, a clear understanding of the dry-type transformer production line is essential for evaluating product quality, manufacturing capacity, and long-term supply stability. This article provides a professional and systematic explanation of the production steps and key equipment used in standardized dry-type transformer manufacturing, aligned with international standards such as IEC, IEEE, and GB.

Overview of the Dry-Type Transformer Production Line

Modern dry-type transformer production lines typically adopt a modular, automated, and process-controlled layout. The complete line covers winding manufacturing, core processing, insulation treatment, epoxy casting or encapsulation, final assembly, factory testing, and finished product packaging. Automation and digital control significantly reduce human error while ensuring consistent electrical performance and mechanical strength.

Core Production Steps of Dry-Type Transformers

Core Manufacturing and Processing

The transformer core is manufactured using high-quality silicon steel sheets with stepped lamination technology to minimize magnetic circuit losses and reduce noise. Fully automatic or semi-automatic stacking machines ensure precise lamination alignment and tight structural integrity.

Core fixing is performed using high-strength bolts or steel binding straps to reduce vibration during operation. In high-performance applications, annealing treatment may be applied to relieve mechanical stress and further improve magnetic properties.

Winding Manufacturing

High-voltage windings are commonly produced using segmented cylindrical winding or continuous winding technology. Insulating materials such as DMD prepreg are laid between layers to enhance dielectric strength. After winding, the coils undergo vacuum pressure impregnation with epoxy resin, followed by high-temperature curing to form a solid and fully encapsulated structure.

Low-voltage windings are manufactured using copper foil, aluminum foil, or insulated conductor wire. Automatic foil winding machines precisely control turn spacing and tension. Coil terminals are connected through copper busbar welding or bolted connections to ensure low resistance and stable current transmission.

Insulation Drying and Curing

Once winding fabrication is completed, vacuum drying removes internal moisture from the insulation system. This step is critical for ensuring low partial discharge levels, high thermal endurance, and long service life. Proper insulation treatment directly impacts transformer reliability under long-term operation.

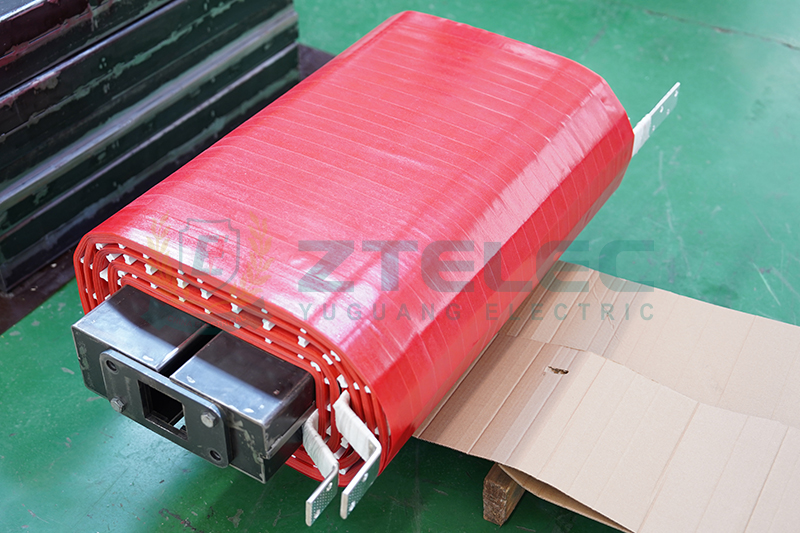

Epoxy Casting or Encapsulation Molding

Epoxy resin casting is carried out in a vacuum environment to fully penetrate winding gaps and eliminate air bubbles. This process forms a dense, uniform insulating body that significantly improves moisture resistance, mechanical strength, and short-circuit withstand capability.

Core and Winding Assembly

After molding, the windings are precisely assembled onto the transformer core. Accurate positioning, clamping, and fixing prevent displacement during transportation and operation, ensuring stable electromagnetic performance.

Final Assembly and Accessory Installation

Cooling fans, temperature monitoring systems, protection devices, and enclosures are installed during final assembly. Functional commissioning ensures the transformer meets operational requirements for various application environments.

Factory Testing and Quality Inspection

Each dry-type transformer undergoes comprehensive factory testing, including no-load loss tests, load loss tests, insulation withstand voltage tests, partial discharge measurements, and temperature rise tests. These inspections ensure full compliance with design specifications and international standards before delivery.

Key Equipment in Dry-Type Transformer Production Lines

The performance and consistency of dry-type transformers largely depend on the quality and automation level of production equipment. Core equipment includes automatic silicon steel cutting and stacking machines for precise core fabrication, high-precision winding machines for accurate coil manufacturing, and vacuum drying ovens for effective moisture removal.

Vacuum casting systems play a decisive role in insulation quality, while curing ovens ensure epoxy resin stability and mechanical strength. Comprehensive testing systems complete all factory acceptance tests, guaranteeing reliable product performance upon delivery.

An efficient dry-type transformer production line reflects the integration of advanced technology, reliable equipment, and standardized management systems. To remain competitive in the global power equipment market, manufacturers must continuously upgrade their production lines toward automation, digitalization, and environmentally friendly manufacturing practices.

If you are seeking a manufacturer with a complete and reliable dry-type transformer production line, feel free to contact us for professional solutions and technical support.

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele