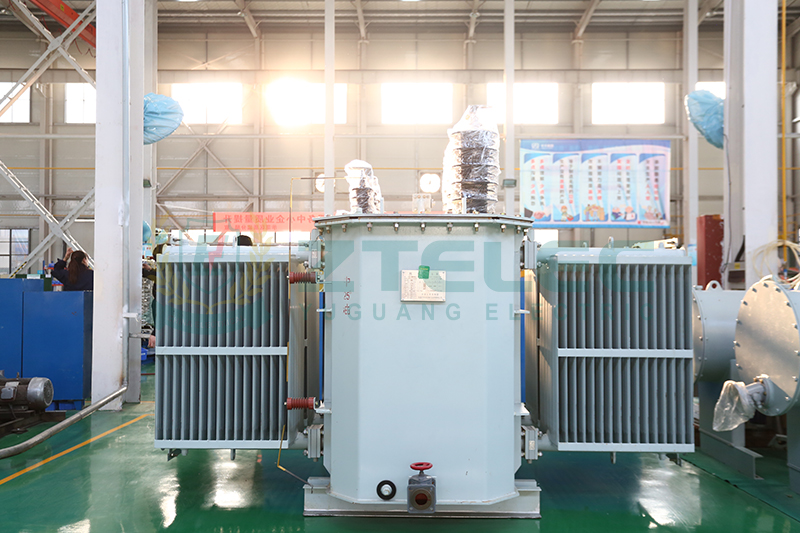

Oil-Immersed Autotransformer: Working Principle and Applications

The oil-immersed autotransformer is an essential component in modern power transmission and distribution systems. It is widely applied in substations, voltage regulation networks, industrial power systems, and new energy grid connections. Compared with traditional two-winding transformers, oil-immersed autotransformers feature a compact structure, higher efficiency, and lower manufacturing costs, making them particularly suitable for medium- and high-voltage systems where voltage ratios are relatively close.

This article provides a comprehensive overview of the working principle, technical advantages, application scenarios, and selection and maintenance considerations of oil-immersed autotransformers, helping power engineers and project planners make informed decisions.

Working Principle of Oil-Immersed Autotransformers

An oil-immersed autotransformer operates using a single continuous winding with multiple tapping points. Voltage transformation is achieved by selecting different taps on the same winding, allowing the primary and secondary sides to share part of the winding electrically.

When alternating current is applied to the primary side, an alternating magnetic flux is generated within the transformer core. This magnetic flux forms a closed magnetic circuit, inducing voltages at different tapping points in proportion to the number of turns. By connecting the load to the appropriate tap, the transformer can perform step-up or step-down voltage conversion.

Unlike a two-winding transformer, energy transfer in an autotransformer occurs through a combination of electromagnetic induction and direct electrical conduction. This hybrid transmission method significantly reduces copper losses and improves overall efficiency.

Core Advantages of Oil-Immersed Autotransformers

High Efficiency and Economic Benefits

Oil-immersed autotransformers require 20% to 30% less copper and core material compared with equivalent two-winding transformers. This reduction directly lowers manufacturing and transportation costs. In addition, lower operating losses translate into considerable energy savings over the equipment’s service life.

Excellent Heat Dissipation Performance

The transformer oil serves both as an insulating medium and an effective coolant. The large oil volume enhances heat dissipation efficiency, allowing the transformer to operate reliably under high load and continuous duty conditions. This design also improves short-term overload capability.

High Reliability and Long Service Life

The oil-immersed insulation system isolates windings from air, preventing oxidation and moisture ingress. Stable thermal performance and effective insulation protection significantly extend the service life of the transformer and reduce the risk of insulation failure.

Typical Applications of Oil-Immersed Autotransformers

Power Transmission and Distribution Systems

Oil-immersed autotransformers are commonly installed in substations with voltage levels such as 220kV, 110kV, and 66kV. They are used for voltage conversion and interconnection between power grids with similar voltage levels.

Grid Voltage Regulation Systems

When equipped with on-load tap changers, oil-immersed autotransformers enable real-time voltage regulation, ensuring stable grid operation under fluctuating load conditions.

Industrial Power Systems

In industries such as metallurgy, chemical processing, power generation, and large motor starting applications, oil-immersed autotransformers are used to match equipment voltage requirements and reduce starting current.

New Energy Grid Connection Systems

Wind power and photovoltaic power stations often use oil-immersed autotransformers in step-up substations to enhance grid connection stability and reduce transmission losses.

Urban Rail Transit Systems

In traction power supply systems for urban rail and metro projects, oil-immersed autotransformers provide reliable voltage conversion and stabilization, supporting safe and efficient train operation.

Selection and Maintenance Guidelines

Key Selection Considerations

When selecting an oil-immersed autotransformer, engineers should calculate capacity based on load characteristics, peak demand, and future expansion plans. The voltage ratio and tap range must match system voltage fluctuations, while impedance should be coordinated with short-circuit capacity to ensure safe operation. Environmental factors such as temperature, altitude, and humidity should also be carefully evaluated.

Maintenance and Operation Management

Routine maintenance includes monitoring oil level and temperature, testing oil quality indicators such as breakdown voltage, moisture content, and acid value, and checking the reliability of electrical connections. Protection devices should be tested and calibrated regularly to ensure correct operation.

Effective oil management is critical. Periodic oil sampling and laboratory analysis help detect early insulation issues. Online oil monitoring systems can provide real-time condition assessment, while oil filtration and regeneration ensure long-term oil quality compliance.

Common warning signs of potential faults include abnormal noise or vibration, unexpected oil temperature rise, gas relay alarms, and abnormal dissolved gas analysis results. Prompt investigation can prevent serious failures.

Oil-Immersed Autotransformer vs. Two-Winding Transformer

| Comparison Item | Autotransformer | Two-Winding Transformer |

|---|---|---|

| Winding Structure | Shared winding | Separate windings |

| Insulation Isolation | Not fully isolated | Fully isolated |

| Cost | Lower | Higher |

| Efficiency | High | Relatively lower |

| Application Scenario | Similar voltage levels | Any voltage level |

Oil-immersed autotransformers offer high efficiency, compact structure, and reliable performance, making them indispensable in modern power systems. By understanding their operating principles, selecting appropriate configurations, and implementing scientific maintenance strategies, power system operators can fully realize their technical and economic advantages.

For power engineering projects that require efficient voltage conversion between similar voltage levels, oil-immersed autotransformers represent a well-balanced solution that combines performance reliability with cost effectiveness.

- more+releated article

- 2026-01-16DDP Diamond Dotted Paper Supplier | Custom &am

- 2026-01-16Oil-Immersed Autotransformer: Working Principl

- 2026-01-15Dry-Type Transformer Production Line: Producti

- 2026-01-15Manufacturing Process and Quality Standards of

- 2026-01-14Oil-Immersed Transformer Production Line: Equi

- 2026-01-14High-Performance High-Density Electrical Lamin

- 2026-01-13Rising Resin Costs Put Pressure on the Semicon

- 2026-01-13Transformer Manufacturing Production Line Proc

- 2026-01-12A Specialized Manufacturer of Oil-Immersed Tra

- 2026-01-09Application Analysis of 11168kVA Oil-Immersed