Differences between FR4 and FR5 fiberglass laminates

FR4 and FR5 are both types of fiberglass-reinforced epoxy laminate materials used in the construction of printed circuit boards (PCBs), but they have some key differences:

Composition:

FR4: Made of woven fiberglass cloth impregnated with an epoxy resin, with a Tg (glass transition temperature) rating indicated by the “4” in FR4.

FR5: Similar to FR4 in composition but typically has a higher Tg rating1.

Glass Transition Temperature (Tg):

FR4: Generally has a Tg rating around 130-140°C, which is the temperature at which the material transitions from a rigid to a more flexible state.

FR5: Has a higher Tg rating, often around 150-170°C or even higher, making it suitable for applications requiring higher-temperature operation or processing.

Temperature Resistance:

FR4: Suitable for standard electronic applications with moderate

operating temperatures.

FR5: Chosen for applications where higher temperature resistance is necessary, such as high-frequency and high-speed communication devices, military applications, and other specialized electronics.

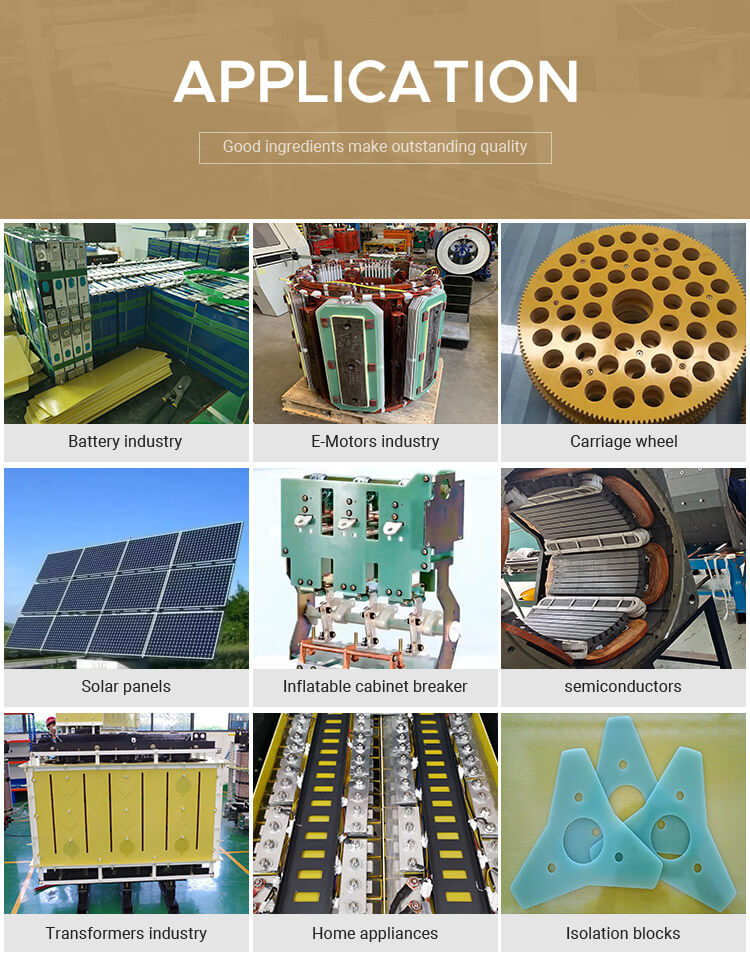

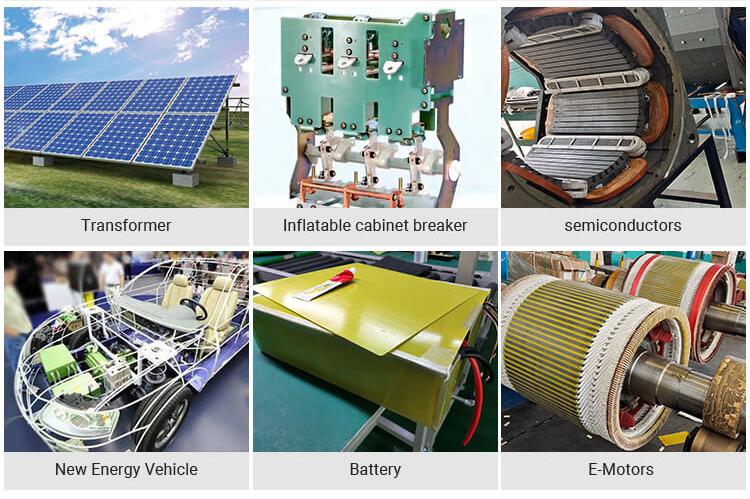

Applications:

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele