Common Uses of Filament Wound Fiberglass Tubing

In power equipment, motors, and new energy systems, the reliability of insulation materials has a significant impact on the safe operation and service life of the equipment. Filament wound fiberglass tubing possesses excellent electrical insulation properties, high mechanical strength, and good weather resistance, thus they are widely used in various electrical and industrial equipment.

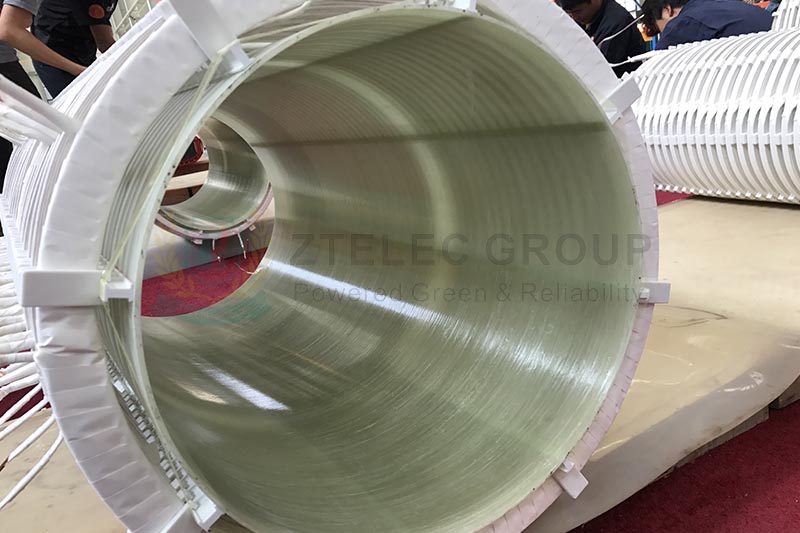

What is Filament Wound Fiberglass Tubing?

Filament wound fiberglass tubing is a composite material tube. Its production process involves impregnating continuous glass fibers with epoxy resin, winding them at a specific angle onto a mandrel, and then curing them.

Compared to fiberglass tubes produced by ordinary pultrusion or molding processes, filament wound fiberglass tubing has a more uniform fiber distribution, a denser structure, and more stable performance.

Key Features of Filament Wound Fiberglass Tubing

Good Electrical Insulation: Suitable for medium and high voltage environments

High Heat Resistance: Standard heat resistance grades are F or H

High Mechanical Strength: Provides both insulation and structural support

Moisture and Corrosion Resistance: Suitable for various complex environments

Customizable Sizes: Inner diameter, wall thickness, etc., can be adjusted as needed

Based on these features, filament wound fiberglass tubing can be used not only as insulating components but also as structural parts in electrical equipment.

Common Applications of Filament Wound Fiberglass Tubing

1. Transformer Insulation and Support

In oil-immersed and dry-type transformers, filament wound fiberglass tubing is commonly used for:

Winding insulation bushings

Tie rods and support columns

Phase-to-phase insulation components

Their good mechanical strength and electrical properties help improve the stability and short-circuit withstand capability of transformer operation.

2. Motor and Generator Insulation Components

In medium and large-sized motors and generators, filament wound fiberglass tubing is mostly used for:

Stator or rotor insulation supports

High-strength insulation sleeves

Axial insulation components

It maintains stable performance even under high-speed and high-temperature operating conditions.

3. High-Voltage Switchgear and Distribution Systems

In high-voltage and medium-voltage switchgear, common applications of filament wound fiberglass tubing include:

Insulating supports

Insulating isolation sleeves

Structural insulation supports

This material is suitable for applications requiring high mechanical strength and insulation distance.

4. New Energy and Power Electronic Equipment

In photovoltaic, wind power, energy storage, and rectifier systems, filament wound fiberglass tubing can be used for:

DC system insulation support

Rectifier transformer insulation structures

High-temperature power electronic equipment insulation components.

Their environmental resistance helps improve the long-term operational reliability of the system.

5. Insulation Applications in Industrial Equipment and Special Environments

In chemical, rail transportation, and mining industries, filament wound fiberglass tubing is commonly used as:

Insulating protective tubing

Structurally reinforced insulation components

Moisture-proof and corrosion-resistant insulation assemblies

Factors to Consider When Selecting Filament Wound Fiberglass Tubing

When selecting filament wound fiberglass tubing based on specific application conditions, the following aspects should be carefully evaluated:

Temperature resistance: Select a suitable resin system (e.g., epoxy, phenolic, polyester, etc.) based on the operating temperature.

Electrical properties: Dielectric strength, volume resistivity, and surface resistivity should meet the applicable standards.

Mechanical properties: Tensile strength, flexural strength, and compressive strength must meet structural requirements.

Chemical resistance: Resistance to the chemical media encountered.

Dimensional accuracy: Tolerances for inner diameter, outer diameter, and wall thickness are crucial for assembly.

Certification requirements: Compliance with relevant industry certifications (e.g., UL, CSA, RoHS, etc.)

As a mature composite insulation material, filament wound fiberglass tubing is widely used in power, motor, and new energy fields. It combines electrical insulation and structural support functions, providing a safe and stable solution for electrical equipment.

Get a customized solution: Choose the right filament wound fiberglass tubing for your project.

If you are looking for insulation materials for a specific project or need to determine the appropriate filament wound fiberglass tubing specifications, we can provide professional consultation and product quotations to support the smooth implementation of your project.

- more+releated article

- 2026-02-04Common Uses of Filament Wound Fiberglass Tubin

- 2026-02-04Dry-Type Transformer Cleaning: Maintenance Pra

- 2026-02-03G10 Machined Parts Manufacturer | High-Tempera

- 2026-02-03How to Choose a 1000 kVA Compact Substation: D

- 2026-02-03Cast-Resin Transformers: Encapsulated and Cast

- 2026-02-032000 kVA Copper Oil Filled Transformer: Featur

- 2026-02-03Encapsulated and Cast-Coil Cast-Resin Transfor

- 2026-02-03Low-Voltage Dry-Type Distribution Transformers

- 2026-02-02Customized G11 Insulating Machined Parts: Proc

- 2026-01-31G11 Epoxy Fiberglass Machined Parts | High-Tem